Prolift Handling are official distribution partner for Modulift Lifting and spreader beams. Based in the UK, they are leading manufacturer of lifting beams in the last two decades.

With this world renouned reputation and superior product range, first class support and advice, you simply cannot go wrong with any of our product range.

What Are The Differences Between Spreader Beams And Lifting Beams ?

| Spreader beams ( Spreader Bar )and lifting beams are two types of rigging equipment commonly used in construction, manufacturing, and other industries for heavy lifting. A lifting beam is a type of beam that is designed to lift and support loads horizontally by spreading the load weight evenly across multiple points. They are typically used for lifting loads that are too heavy or bulky for normal lifting equipment to handle safely. On the other hand, a spreader beam is a specialized lifting device that is designed to spread a load weight over a wider area, providing support and stability during lifting. These are typically used in applications where a load is too heavy or complex for a single lifting point. They are also useful for maintaining a safe working load distribution during lifting. |

Adjustable Lifting Spreader Beams

Applications of Adjustable Lifting Beams:

Construction:

These are are widely employed in construction projects for lifting and moving precast concrete panels, steel girders, and heavy construction materials.

Oil and Gas:

In the oil and gas industry, they are essential for handling equipment and materials, such as drilling rigs, wellheads, and pipelines

Energy:

They play a crucial role in the energy sector, particularly in lifting wind turbine components, solar panels, and power transmission lines.

Choosing The One Which Best Suits Your Needs.

With a variety of adjustable lifting beams available in the market, selecting the right one for your specific needs requires careful consideration. Here are some factors to consider when making your choice:

Choose one that can accommodate the dimensions of the load you need to lift.'

Select one made from durable materials that can withstand the environmental conditions of your worksite.

Opt for beams that are certified by reputable organizations to ensure they meet safety standards

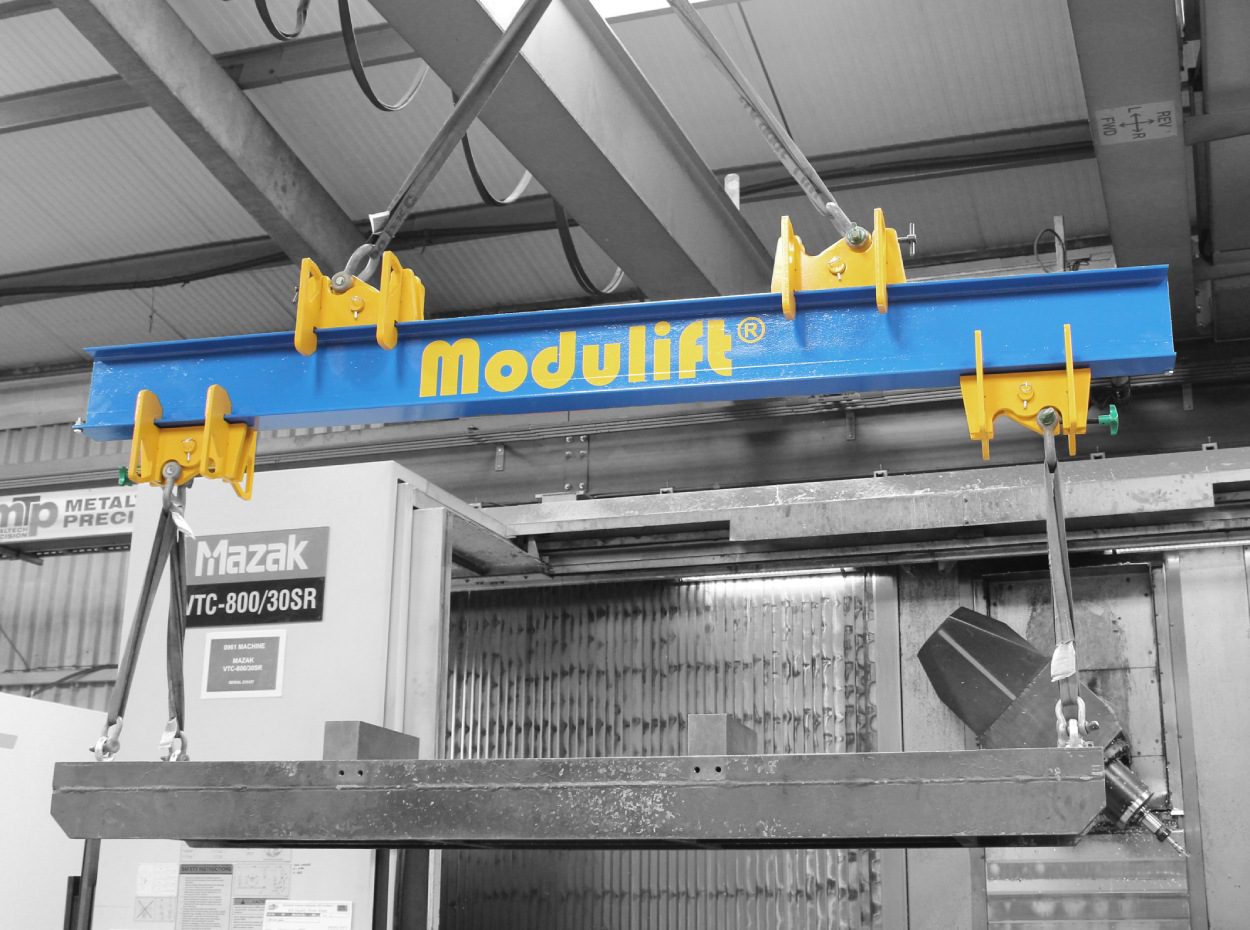

The Modulift Adjustable / Spreader Beam (MOD CLS)

| can now lift up to 27t and has a new and improved clamp system, tested to the highest standards, enabling safe lifting from multiple points. Key Benefits :

|  |

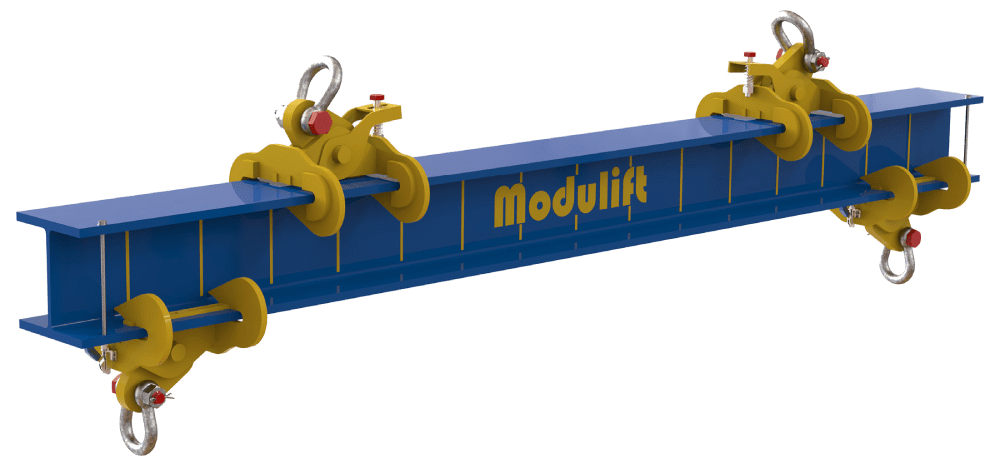

Adjustable Modular Lifting Beams

| In the world of heavy lifting, the ability to adapt is crucial. Adjustable modular lifting beams, also known as spreader beams, have emerged as revolutionary tools that break free from the limitations of traditional fixed-length beams. These ingenious devices, made up of interchangeable components, easily transform to suit a wide range of lifting tasks, offering a level of versatility that redefines the lifting landscape. At the heart of these adaptable marvels lies a modular design, where interchangeable end units, struts, and drop links work together seamlessly. This unique arrangement allows you to quickly reconfigure it, adapting it to handle a diverse range of lifting scenarios. Whether you’re dealing with pipes, precast concrete elements, or even heavy machinery, these adapt effortlessly rise to the challenge.  |

In the dynamic world of construction, oil and gas, and energy, adaptability is key. Traditional fixed-length lifting beams often fall short when faced with the ever-changing demands of these industries. Enter adjustable modular lifting beams – the game-changers that redefine versatility, safety, and efficiency.

Embrace Versatility Like Never Before

Adjustable modular lifting beams, also known as spreader beams, are not just another lifting tool; they’re a transformative solution. Their modular design, composed of interchangeable components, allows for quick and effortless reconfiguration to suit a wide array of lifting tasks. Whether you’re handling pipes, beams, precast concrete elements, or heavy machinery, these adaptable beams seamlessly accommodate your needs.

The Perfect Combination

Safety is paramount in demanding industries. Adjustable modular lifting beams are engineered to meet the highest safety standards, undergoing rigorous load testing to ensure secure and stable lifting operations. With these beams, you can tackle even the heaviest loads with confidence, knowing that safety is never compromised.

The need for multiple fixed-length lifting beams is a thing of the past. Adjustable modular lifting beams eliminate this redundancy, saving you time and money. With just one beam, you can handle a multitude of lifting tasks, streamlining your operations and optimizing your resources.

This new adjustable modular lifting (AML) beam offers the same flexibility and cost-effective benefits as the high quality Modulift Spreader Beams but has multiple pad eyes, so the beam can adapt to lift various weights and sizes.

Available in a series of three: Light (up to 50t), Medium (up to 170t) and Heavy (up to 240t)

Order any length from 1m upwards and add to your beam as required to achieve spans up to 19m

Use as a lifting beam or a semi spreader beam

Modular system reduces transport costs as longest component length is 6m

Reduced handling requirements.

Don’t let outdated lifting methods hinder your progress. Embrace the versatility and efficiency of adjustable modular lifting beams and elevate your operations to new heights.

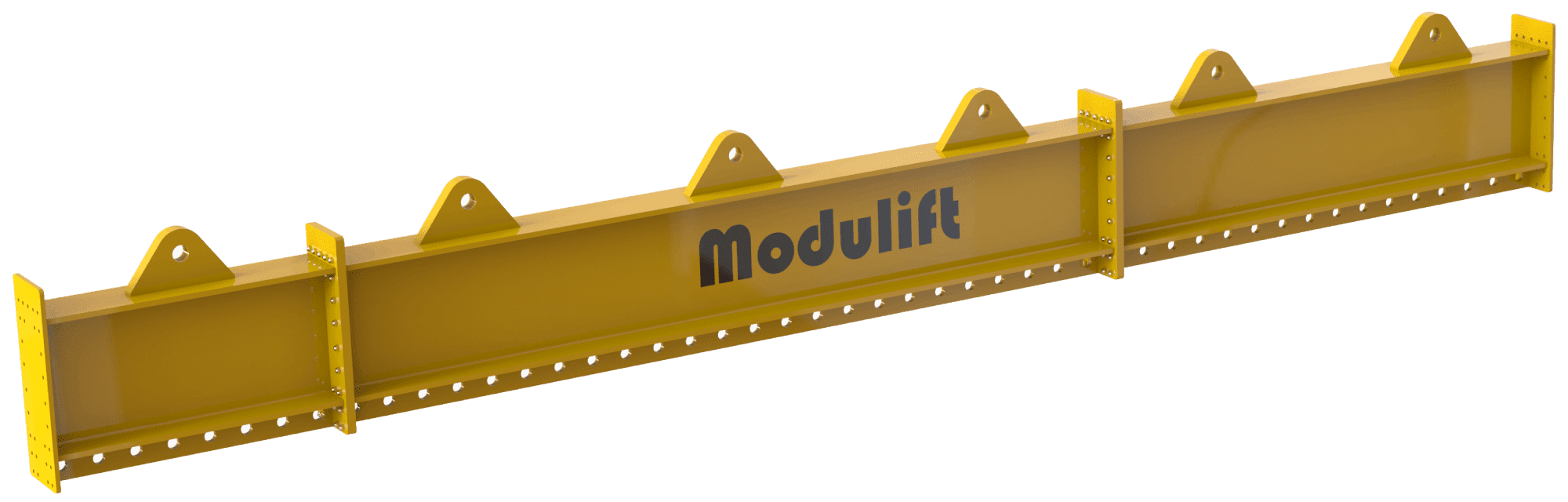

Modular Spreader Beams

Modulift’s modular spreader beams, available through Prolift Handling Ltd in Ireland, are the perfect lifting solution for a wide-ranging set of industries, including construction, oil and gas, and energy and can be tailored to meet specific lifting requirements.

What Are Modular Spreader Beams?

These are constructed of interchangeable components such as end units, struts, and drop links, allowing customization for length, width, and weight capacity. This makes them more versatile and adaptable than traditional spreader beams.

Key Benefits:

- Versatility: They can lift a wide array of loads, from pipes to steel beams and precast concrete.

- Adaptability: Modular spreader beams can be quickly adjusted for different jobs, saving time and money.

- Safety: They are certified and load-tested for secure lifting, ensuring the safety of your employees and property.

- Durability: Modular types are built with high-quality materials and are designed to withstand demanding environments.

Construction:

They are ideal for lifting heavy materials such as concrete beams and steel girders. They are also used to lift and move heavy equipment, such as excavators, cranes, and bulldozers.

Oil and Gas:

They are well suited for handling equipment and materials in drilling rigs, wellheads, and pipelines.

Energy:

They are perfect for lifting wind turbine components, solar panels, and power transmission lines.

As a leading supplier of Modulift spreader beams in Ireland, Prolift Handling Ltd offers expert advice and a variety of options to meet your lifting needs. We also offer competitive prices and fast delivery times.

The modular configuration and interchangeable components enable the Spreaders to be reused over many lifts. Designed by the engineering experts and manufactured in Modulift’s specialist facilities; these are the best on the market.

|  |

Load Monitoring Spreader Beam

They are equipped with load cells, which are sensors that convert the force of a load into an electrical signal. This signal is then processed and displayed on a readout unit, allowing the operator to monitor the load weight in real time.

There are several benefits to using load monitoring spreader beams. They can help to:

- Improve safety: By monitoring the load weight, operators can ensure that the beam is not overloaded, which can help to prevent accidents.

- Increase efficiency: By knowing the exact weight of the load, operators can optimize lifting procedures and avoid unnecessary downtime.

- Comply with regulations: In some industries, there are regulations that require the use of load monitoring spreader beams for certain lifting tasks.

- Lifting precast concrete panels: Load monitoring spreader beams can be used to lift precast concrete panels safely and efficiently.

- Moving heavy machinery: These can be used to move heavy machinery, such as generators and transformers.

- Positioning offshore structures: They can be used to position offshore structures, such as oil rigs and wind turbines.

Modulift has produced the WORLDS FIRST load monitoring Spreader Beam, with an integrated loadcell (Active Link) giving you instant wireless data logging!

The innovative Active Link provides wireless real-time data by measuring the load at either end of the spreader beam. It is capable of both weighing and dynamic load monitoring. Data is transmitted wirelessly to a USB transceiver that must be connected to a Windows computer or tablet with a spare USB port.

|

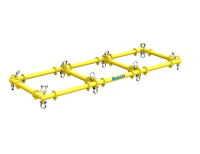

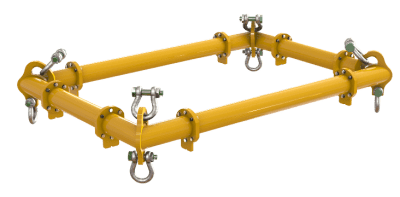

Spreader Frames ( Modular )

Modular spreader frames are made up of interchangeable pieces, like LEGOs. This means that you can quickly and easily change the size and shape of the frame to lift different things. For example, you could use a short, wide frame to lift a pipe, or a tall, narrow frame to lift a beam.

They are also safer than traditional lifting beams. They are designed to meet strict safety standards and they undergo rigorous testing to make sure they can handle the weight they’re lifting.

If you need to lift things in different ways, modular spreader frames are a great option. They are versatile, safe, and easy to use.

- Versatility: Modular spreader frames can handle a wide variety of loads, from pipes and beams to precast concrete elements and heavy machinery. Their modular design allows them to be adapted to different load shapes, sizes, and weights.

- Adaptability:Unlike fixed-length beams, modular spreader frames can be quickly reconfigured to accommodate different lifting scenarios. This eliminates the need for multiple beams, saving time and money.

- Safety: Modular spreader frames are designed to meet stringent safety standards and undergo rigorous load testing to ensure secure and stable lifting operations.

- Durability: Modular spreader frames are designed to meet stringent safety standards and undergo rigorous load testing to ensure secure and stable lifting operations.

These are widely used in various industries, including:

- Construction: They are essential for lifting and moving precast concrete panels, steel girders, and heavy construction materials.

- Oil and Gas: They are used for handling equipment and materials, such as drilling rigs, wellheads, and pipelines.

- Energy: They play a crucial role in lifting wind turbine components, solar panels, and power transmission lines.

Several factors should be considered when selecting a modular spreader frame for your specific needs:

- Load Capacity: Ensure the beam’s rated load capacity exceeds the weight of the heaviest load you intend to lift.

- Beam Length and Width: Choose a beam that can accommodate the dimensions of the load you need to lift.

- Material: Select a beam made from durable materials that can withstand the environmental conditions of your worksite.

- Certification: Opt for beams that are certified by reputable organizations to ensure they meet safety standards.

|  |

This Spreader Frame is also designed for where there are height restrictions, as the height of the rig will be lower than a ‘1 over 2’ rig.

The CMOD Spreader Frame is currently available from the CMOD 6 up to the CMOD 250. The systems will lift up to 300t.

Spreader Beam Safety

The Role Of Artificial Intelligence & Spreader Beam Technologies

AI technologies are revolutionizing the way spreader beams and lifting beams are designed, manufactured, and used. The use of AI technologies has increased the accuracy and efficiency of these resources, making them safer and more effective in lifting heavy loads.

AI-powered sensors and cameras are used to monitor the weight and balance of the load, providing real-time data to improve decision-making and reducing the risk of accidents.

Machine learning algorithms are used to optimize beam design, considering factors such as load capacity, material strength, and environmental conditions.

AI-powered robotics can also automate the lifting process, providing a more efficient and cost-effective way of moving heavy materials.

Overall, the use of AI technologies is improving the safety, accuracy, and efficiency of spreader beams and lifting beams in various industries, making them an essential component of the modern workplace.