Monday 19th August 2024

Overview

When it comes to working at heights, safety is critical. Whether you are on a construction site, involved in industrial maintenance, or performing any task that requires elevated work, selecting the right height safety equipment is the most important thing. In this guide we will help you navigate the essential gear needed to work safely on height or in elevated areas. From harnesses and belts to fall arresters and rescue kits, understanding the function and correct usage of each piece of equipment is vital to make sure maximum safety. Our comprehensive selection guide will assist you in choosing the right products tailored to your specific needs, ensuring compliance with safety standards while providing peace of mind.

To ensure Our customers make the most informed decisions, we’ve organised this guide in a logical sequence, covering each essential piece of height safety equipment. Here’s how the guide is structured:

1. Safety Harness and Work Positioning Belts

2. Fall Arrest Equipment

3. Safety Lanyards

4. Connectors

5. Anchorages

6. Rope Access

7. Rescue and Evacuation

8. Kits

Safety Harness and Work Positioning Belts

A Safety harness is a body support system intended to stop falls and keep the user in the best conditions while awaiting the rescue.  The attachment points are static strength> 15 kN.

The attachment points are static strength> 15 kN.

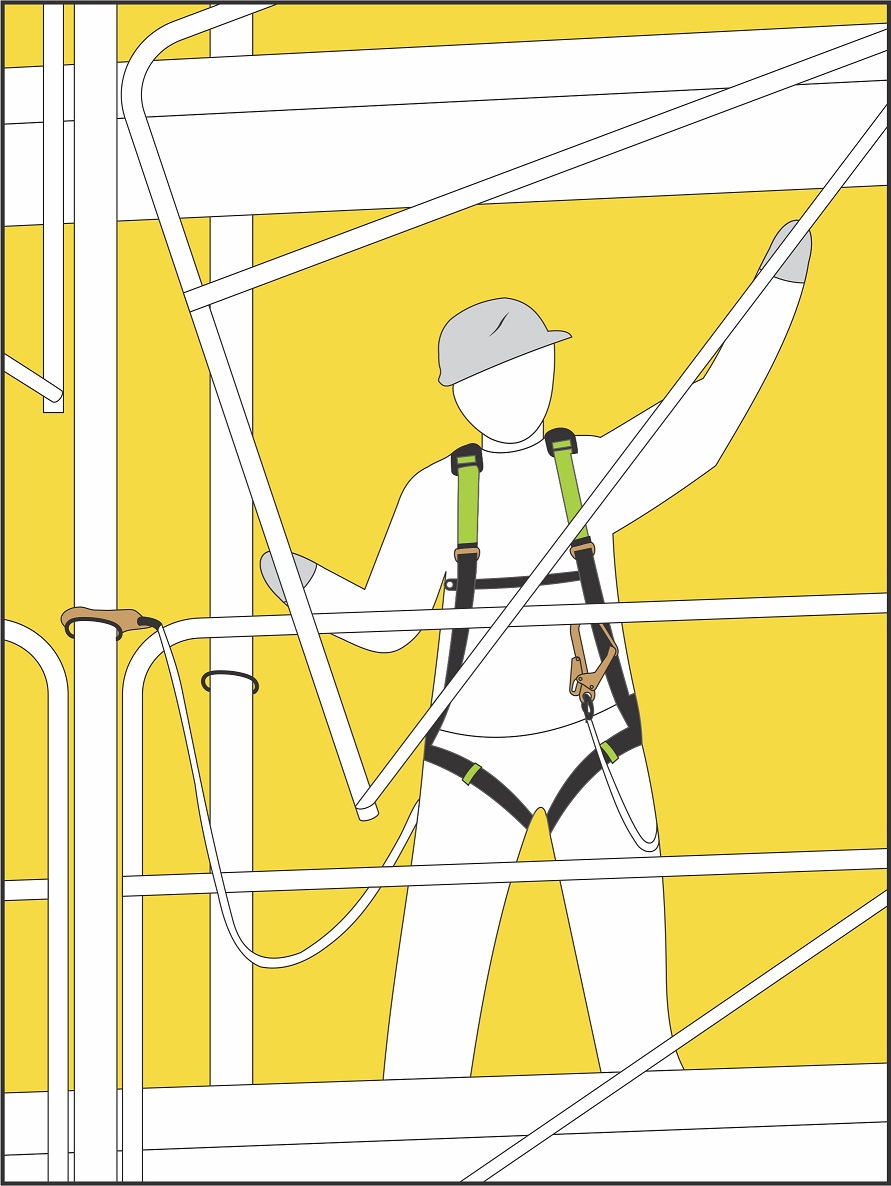

A work positioning belt is a device that allows a user to be held in a position having hands free. The attachment points are static strength> 15 kN.

A work positioning belt must not be used as a fall arrest device.

A work positioning belt must not be used as a fall arrest device.

Selecting one's harness properly entails asking the right questions:

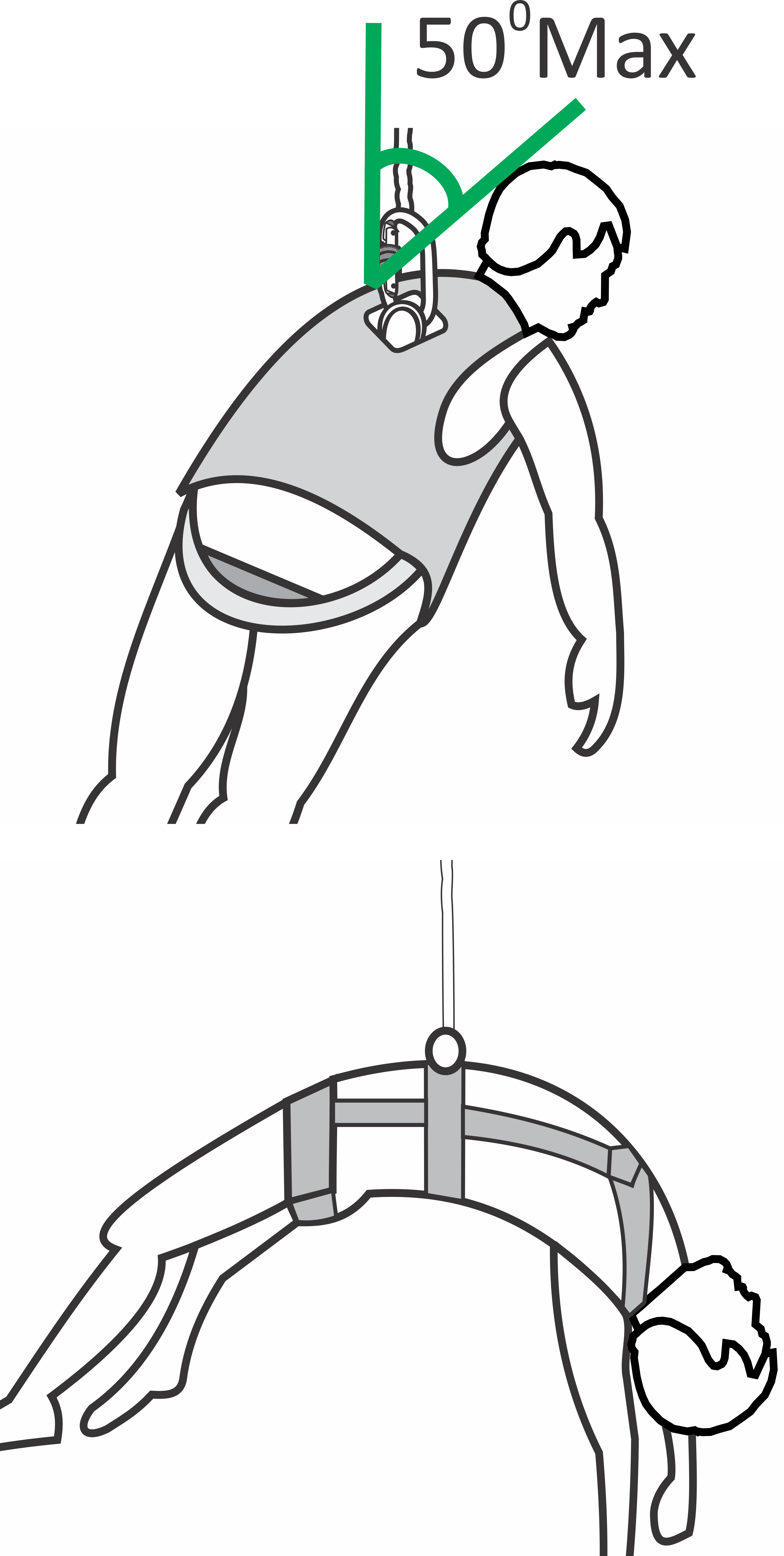

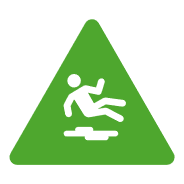

Size: The chart below indicates the body's measures. For the wearing of a harness over clothing, the harness'adjustments allow to obtain the right size.

* Values given as an indication only. May fit slightly smaller or taller heights. All values expressed in cms.

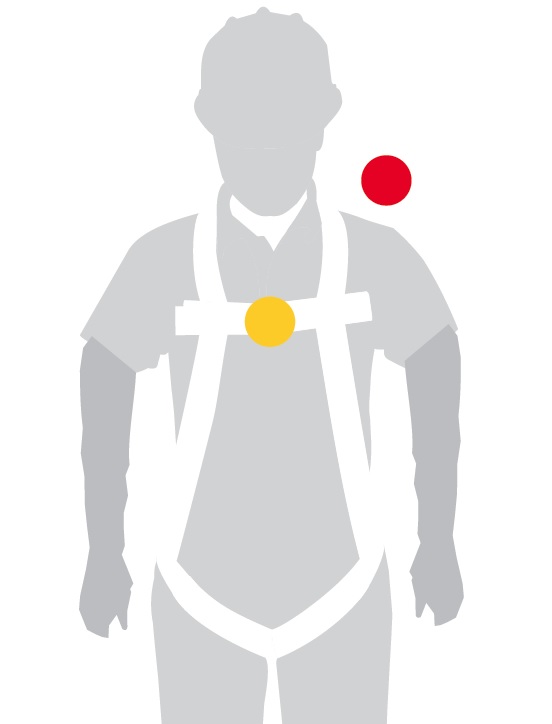

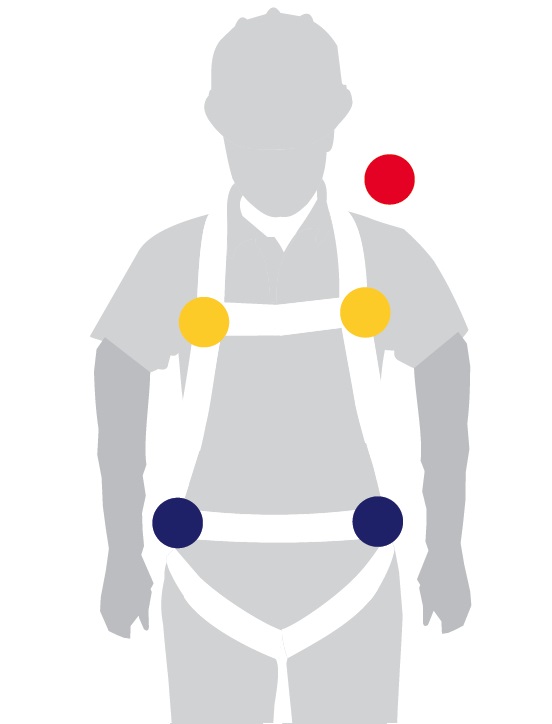

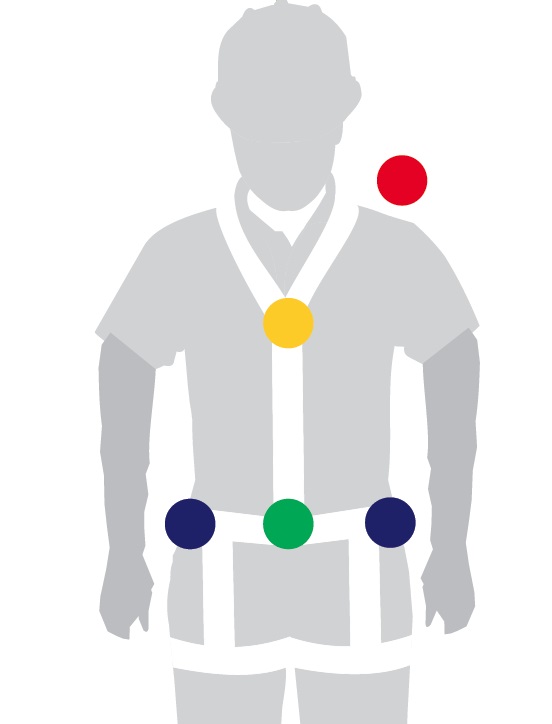

2) Which attachments do I need?

Attachment Points:

A B C

|  |  |

A) With 1 or 2 attachment points (dorsal and sternal)

B) With 1 or 2 attachment points + 2 work positioning points (lateral)

C) With 1 or 2 attachment points + 2 work positioning points + 1 suspension point (ventral)

3) What is my work situation? Do I work in a specific environment?

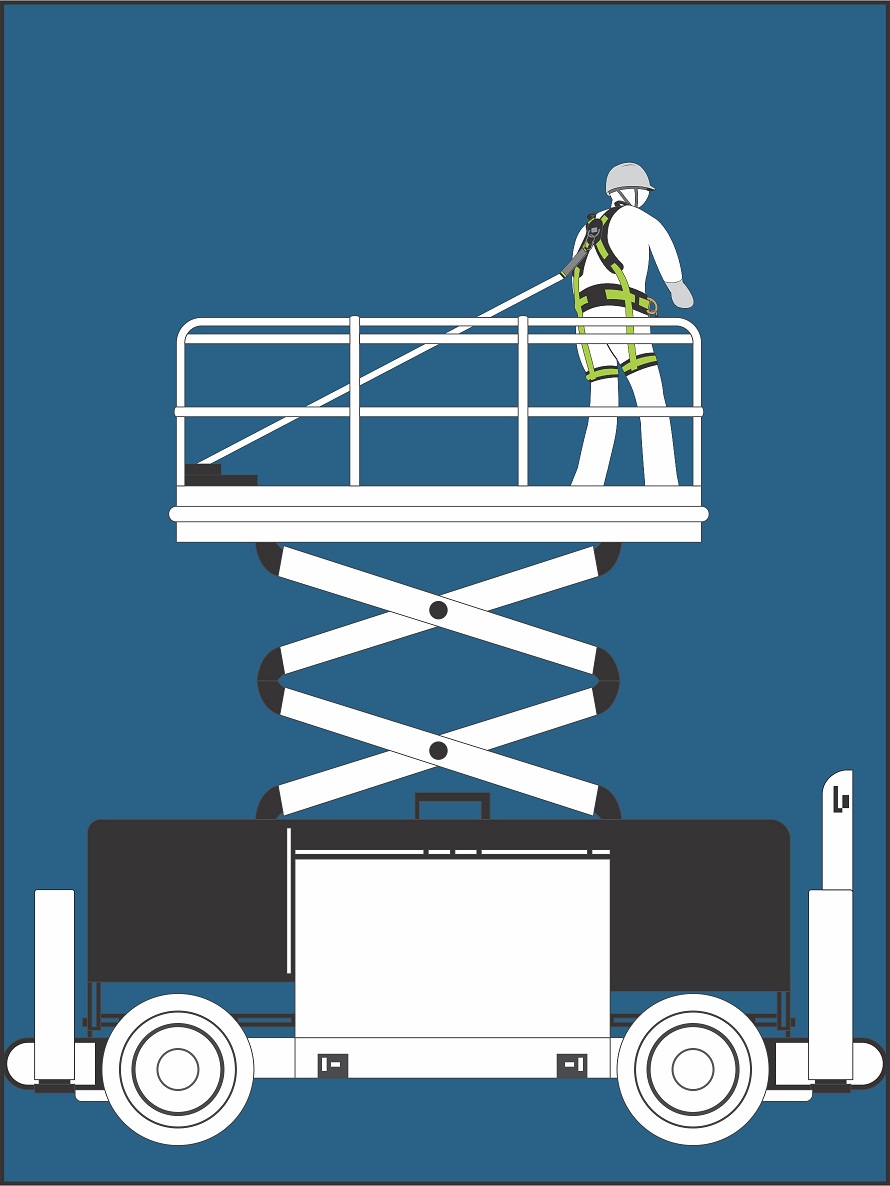

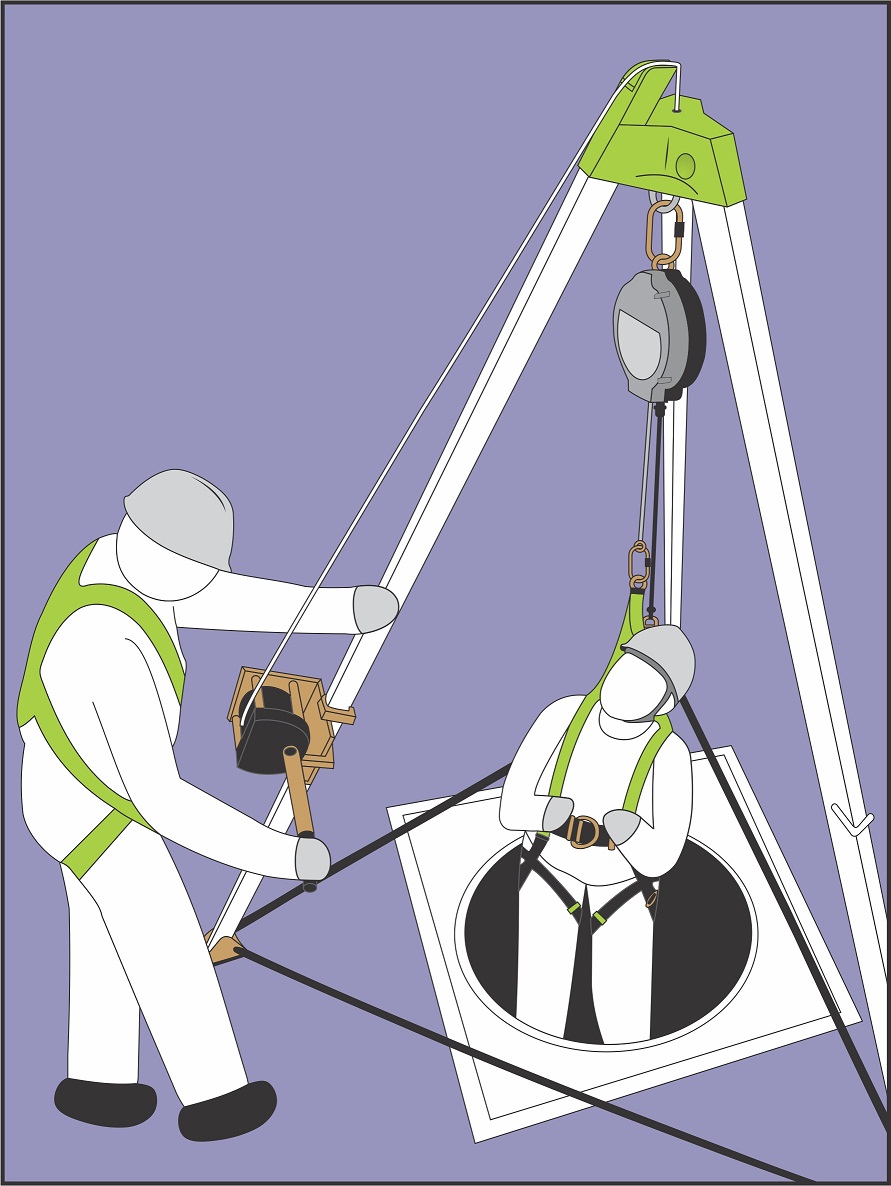

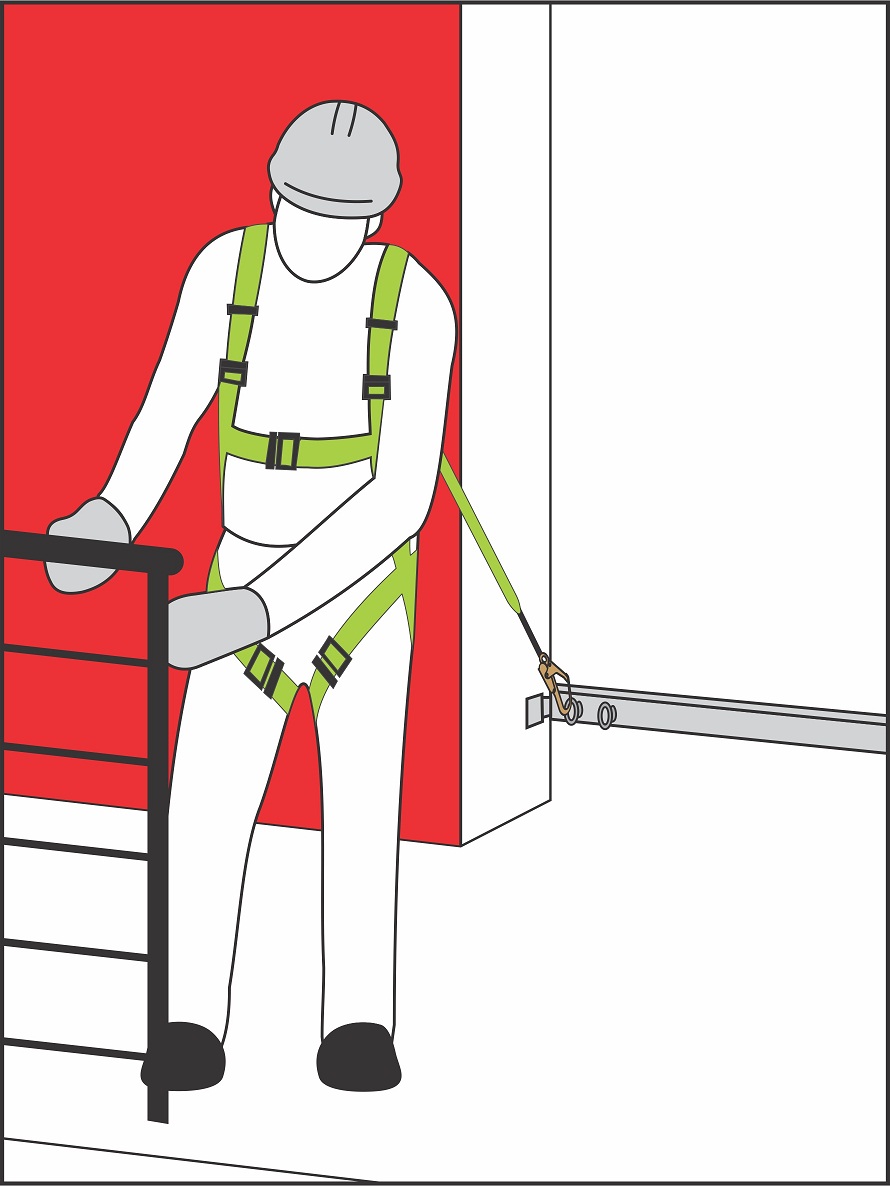

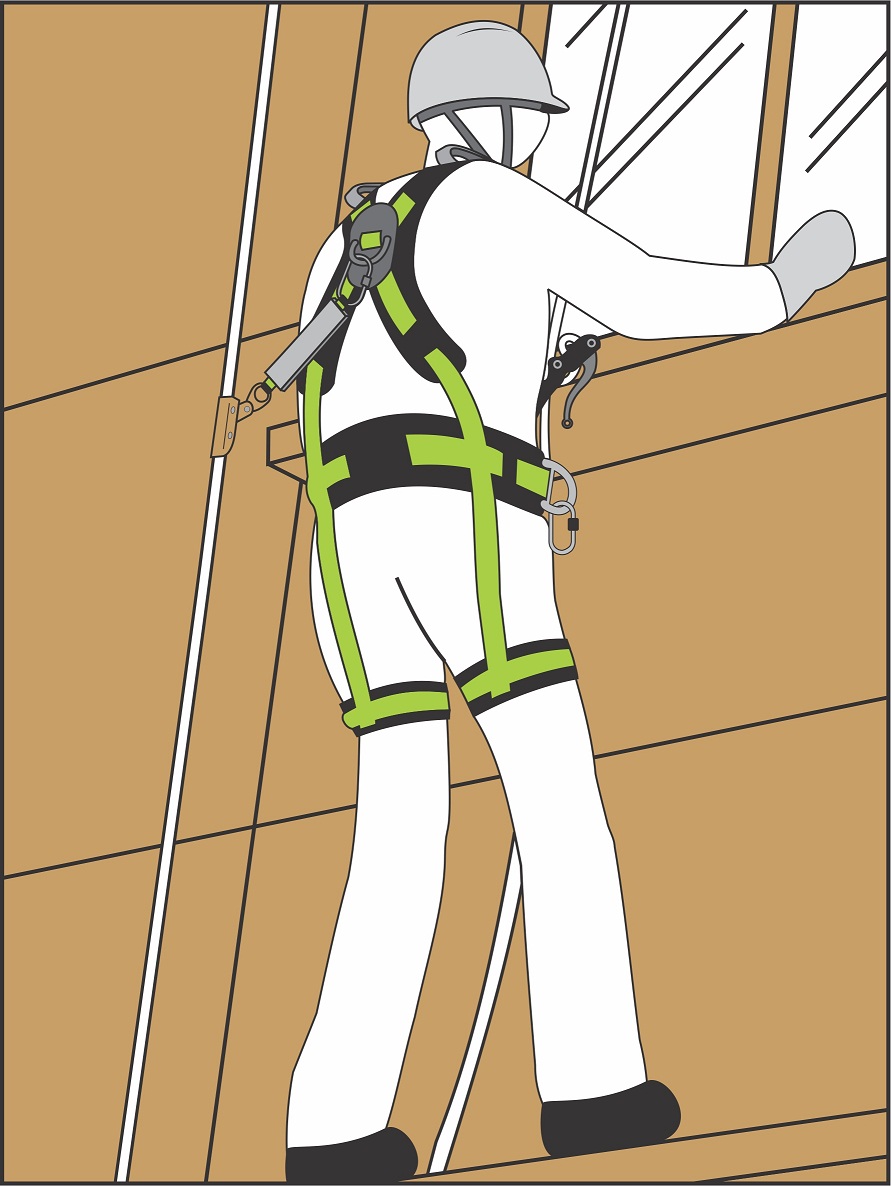

|  |  |  |  |  |

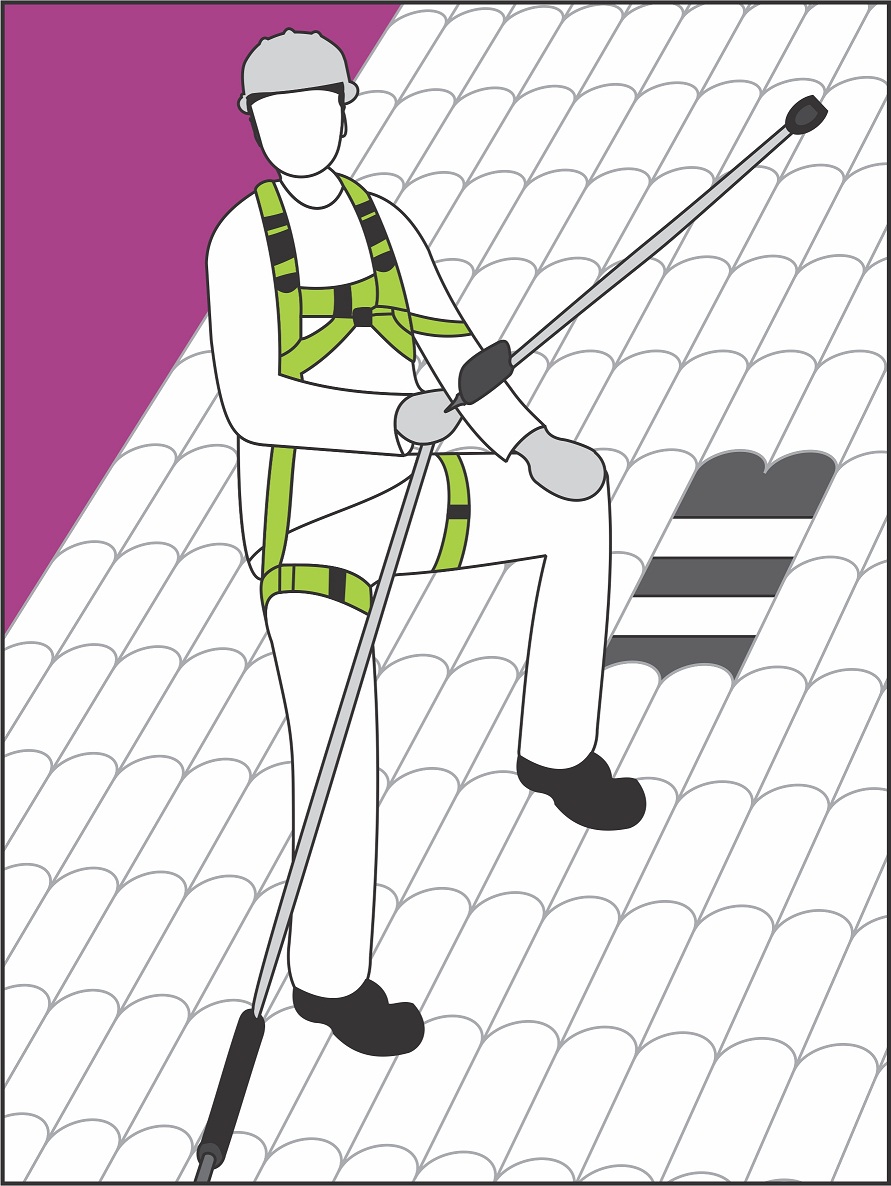

| Cherry picker | Work station prevention | Confined space | Door Frame work | Double rope descent | Inclined plan |

|  |  |  |  |  |

| Horizontal Plan | Work Station Holding | Fixed Ladder | Rescue - Evacuation | Scaffolding | Self-evacuation |

The material of construction of the webbing of our KRATOS Harnesses is Polyester. Since this has the least elongation properties as compared to other materials, the Harness does not stretch dangerously when subjected to a fall. The Wearer hence does not risk slipping out of the harness.

Hold the Harness by the Back D-ring, and allow the straps to fall in place. The Harness has clear and separate colours for the shoulder and thigh straps for them to be easily distinguished;

- inspect the harness webbing for any cuts, burns or damages;

- check the stitches for their continuity;

- carefully look for any evidence of corrosion on the metal parts.

Fall Arrest Equipment

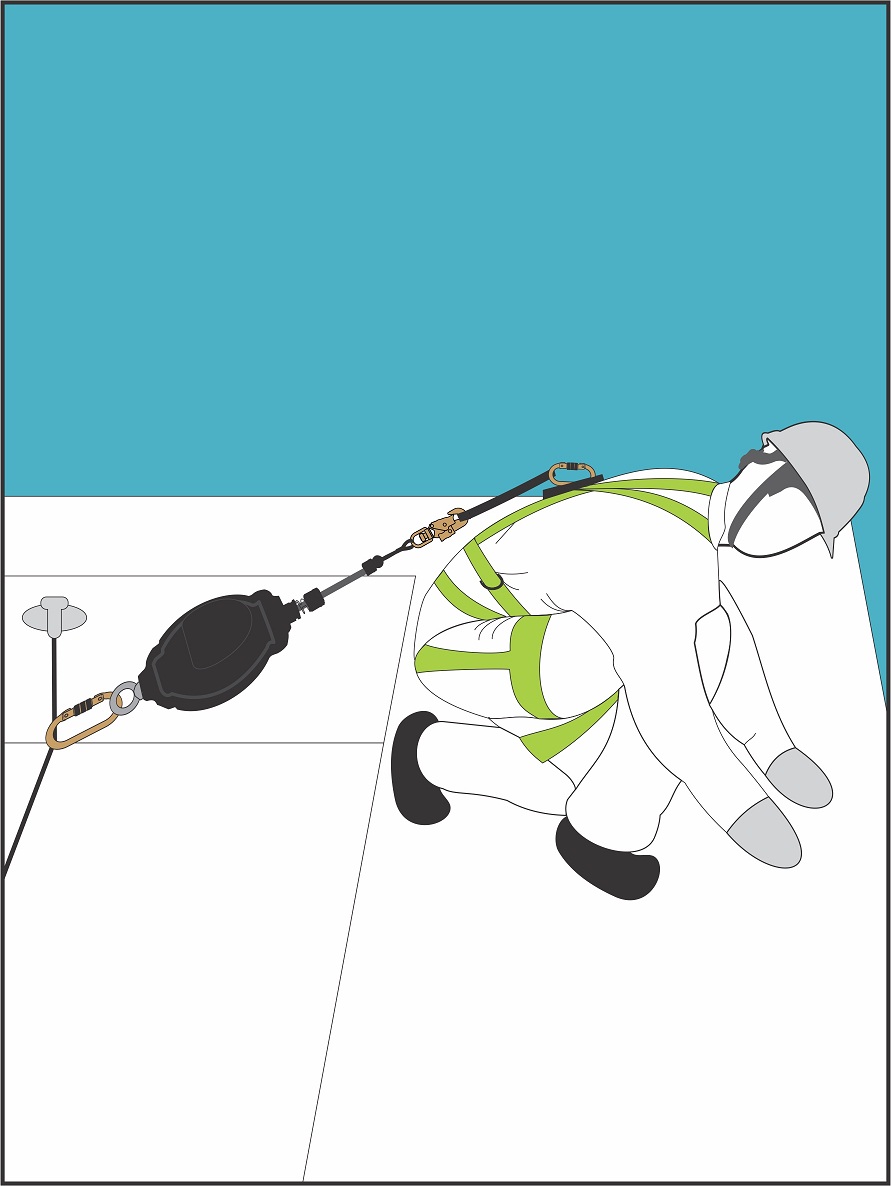

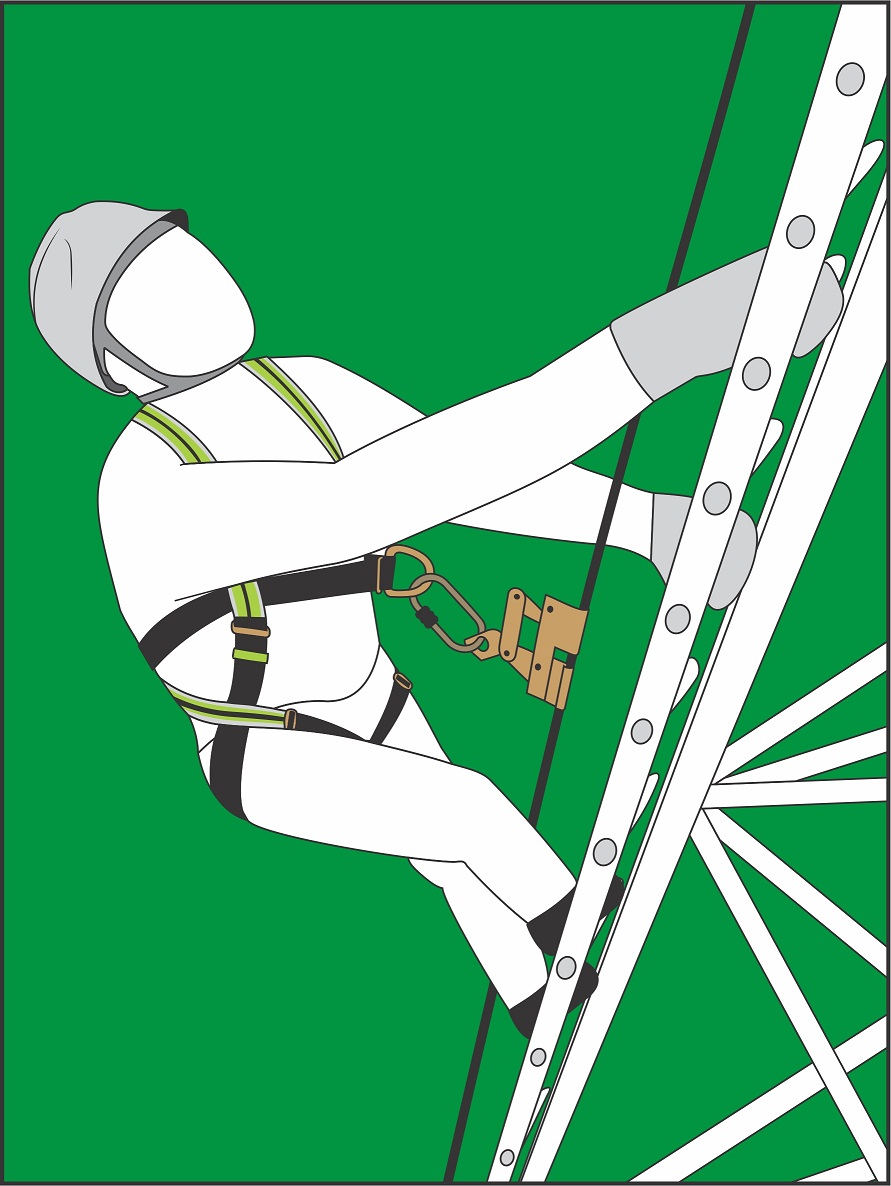

EN353-2 : A fall arrester on flexible anchor line is a device that automatically blocks and stops on the vertical support when the user falls. The anchor line can be a cable (flexible) or a rope (twisted or braided). These flexible anchor lines must be weighted with a counterweight. Breaking strength of these systems> 15 kN.

EN360 : A retractable fall arrester is a device equipped with a lanyard (on cable or webbing) kept in tension. It follows the movements of user. The system blocks and stops automatically when the user falls. These come in different lengths. Breaking strength > 12 kN (for cable lanyard) or > 15kN (for textile lanyard) Whatever the fall arrest system choosen (fall arrester on anchor line, retractable fall arrester, energy absorbing lanyard) it guarantees a fall arrest by limiting the impact on the human body at 6kN maxi.

- If the movement is purely vertical (along a scale for example) we always favour a fall arrester on anchor line

- These have the advantage of being installed (for some) permanently on the structure.

- If the movement can be horizontal & vertical we will prefer a retractable fall arrester.

- It's the fall arrest system that brings greatest freedom of movements.

- The fall arrester on anchor line must always be used directly below the anchor point.

- The retractable fall arresters are ideal for work of low-rise because the blockage is almost instantaneous, limiting the required clearance

- For the work on an inclined plane with fall arrester on anchor line, it is necessary that it be equipped with a manual locking system.

Safety Lanyards

- A restraint lanyard should be used only when you want to prevent a user from accessing an area where there is a risk of falling.

- The Forked lanyards are designed to be used in the same way but for passing intermediate anchor points.

- A work positioning lanyard could be used when there is no risk of falling, otherwise it must be used with a suitable fall arrest system.

RAPPEL: Lanyards without the energy absorber should never be used as a fall arrest system

To be used regularly and or for long-term use

Whatever type of lanyard, the performances are identical, so it is above all a personal choice, but it must be based on the intensity of use.

When choosing the product it will be necessary to take into account the importance of connectors

Connectors

How to choose ?

Different criteria must be taken into consideration

- Opening / locking system:

- Screw locking system : to be reserved for occasional manipulation;

- Automatic locking system : to be used for frequent handling.

- Oval, use essentially with equipment that have 2 points in support on the connector (eg: pulley)

- Asymmetric, used in priority because it allows the proper positioning between the two connected components;

- Large size, used to anchor on metal structures or large sizes;

- Quick link, used when you want to make a quasi permanent connection between two components.

Material:

- Steel, adapted to difficult conditions, these connectors are mainly used for fixed anchors or for connecting to metal structures;

- Aluminium, to be preferred when weight is an important criterion for the work to be performed (eg,rescue).

Connector with an opening<30 mm, mainly used as connection element;

The resistance must also be taken into account when choosing connectors

Note: All our connectors are supplied with a steel anti corrosion zinc electroplating which provides them an excellent corrosion resistance.

ANCHORAGES

EN795 : The anchor point is a point where the fall arrest system is safely attached to ensure the security of the user. There are different kinds of anchor points:

Type A: Anchoring device requiring the fixing of one more structural anchors

Type B: Anchoring device not requiring the fixing of one more structural anchors

Type C: Anchor device using horizontal flexible anchor lines

Type D: Anchor device using horizontal rigid anchor lines

Type E: Deadweight anchoring device

Use : There is no good fall arrest system without a good anchorage point. Whatever the type of intervention to achieve and that it is temporary or regular, it is essential to correctly choose its anchor point and verify that the host structure (building, steel structure, tower) is sufficiently resistant.

How to choose ?

The anchor point is undoubtedly the part of a fall arrest system that is tricky to choose to ensure optimum safety. When choosing the anchor point the first thing to do is to determine where to install it.

For this we must take into account the following aspects:

- Static strength of the anchor point : > 12 kN

- Installation height: high enough compared to the first potential obstacle in case of a fall (see fall factor diagram)

- Situation: in the vertical workstation to avoid risks of pendulum effect (see pendulum effect diagram)

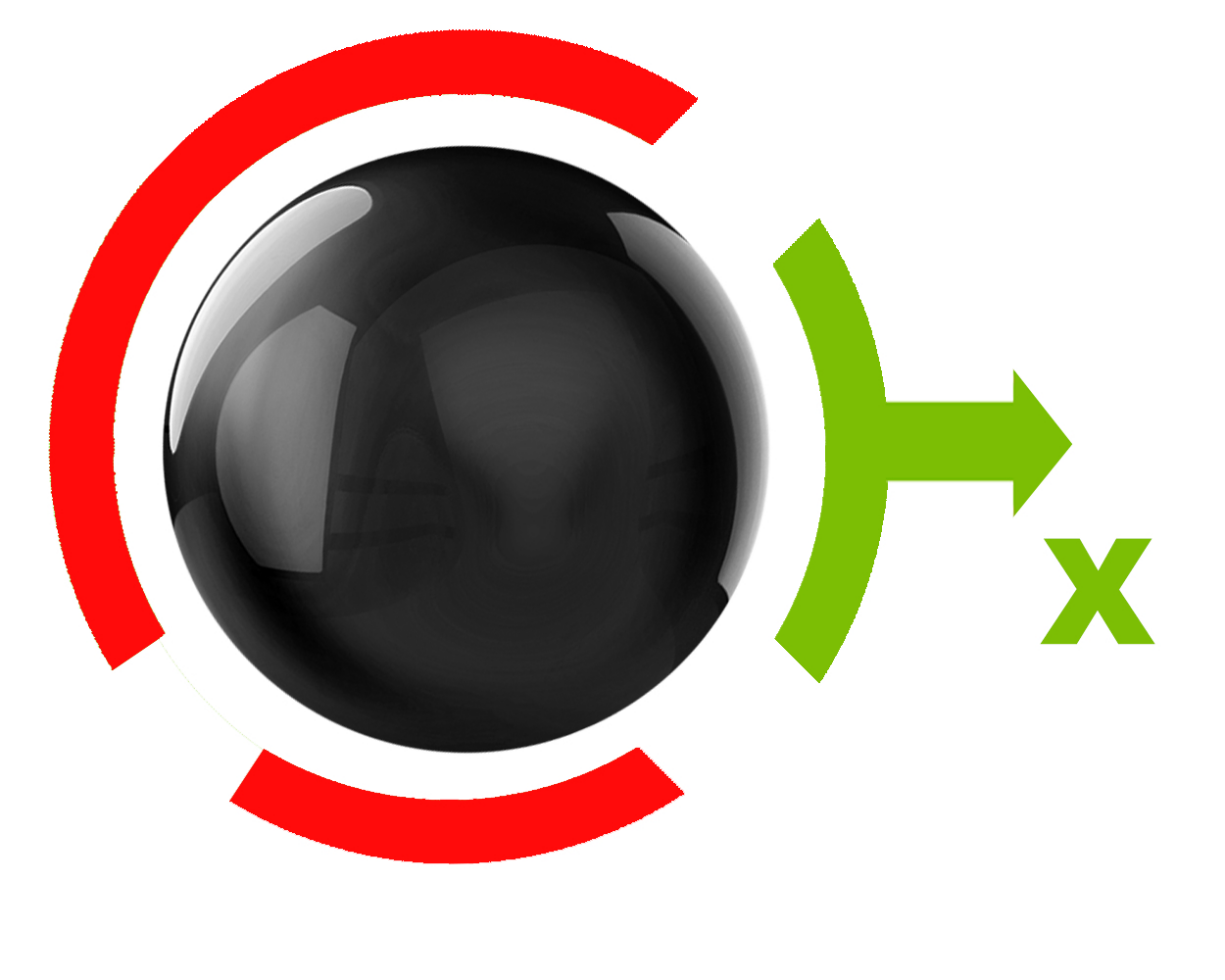

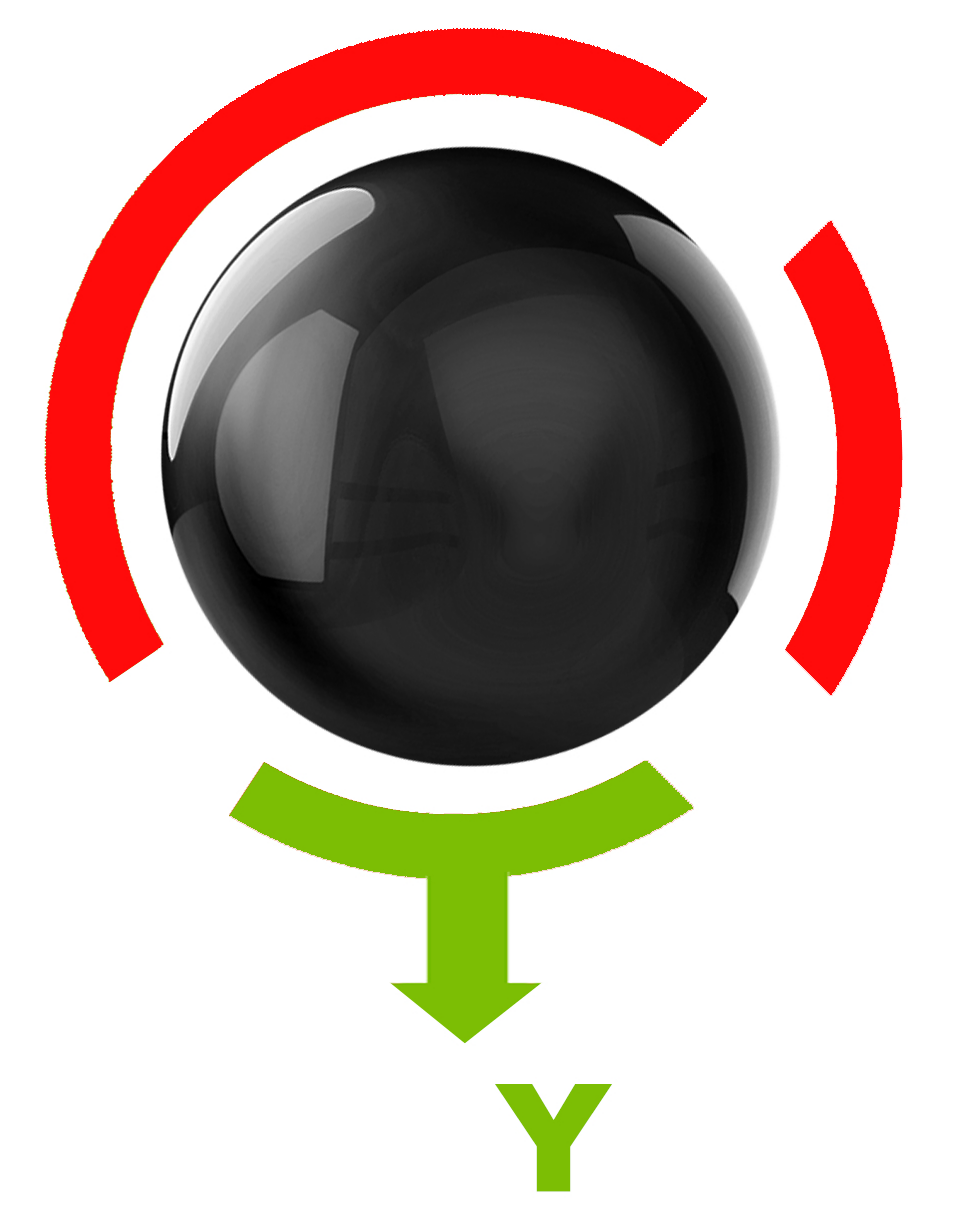

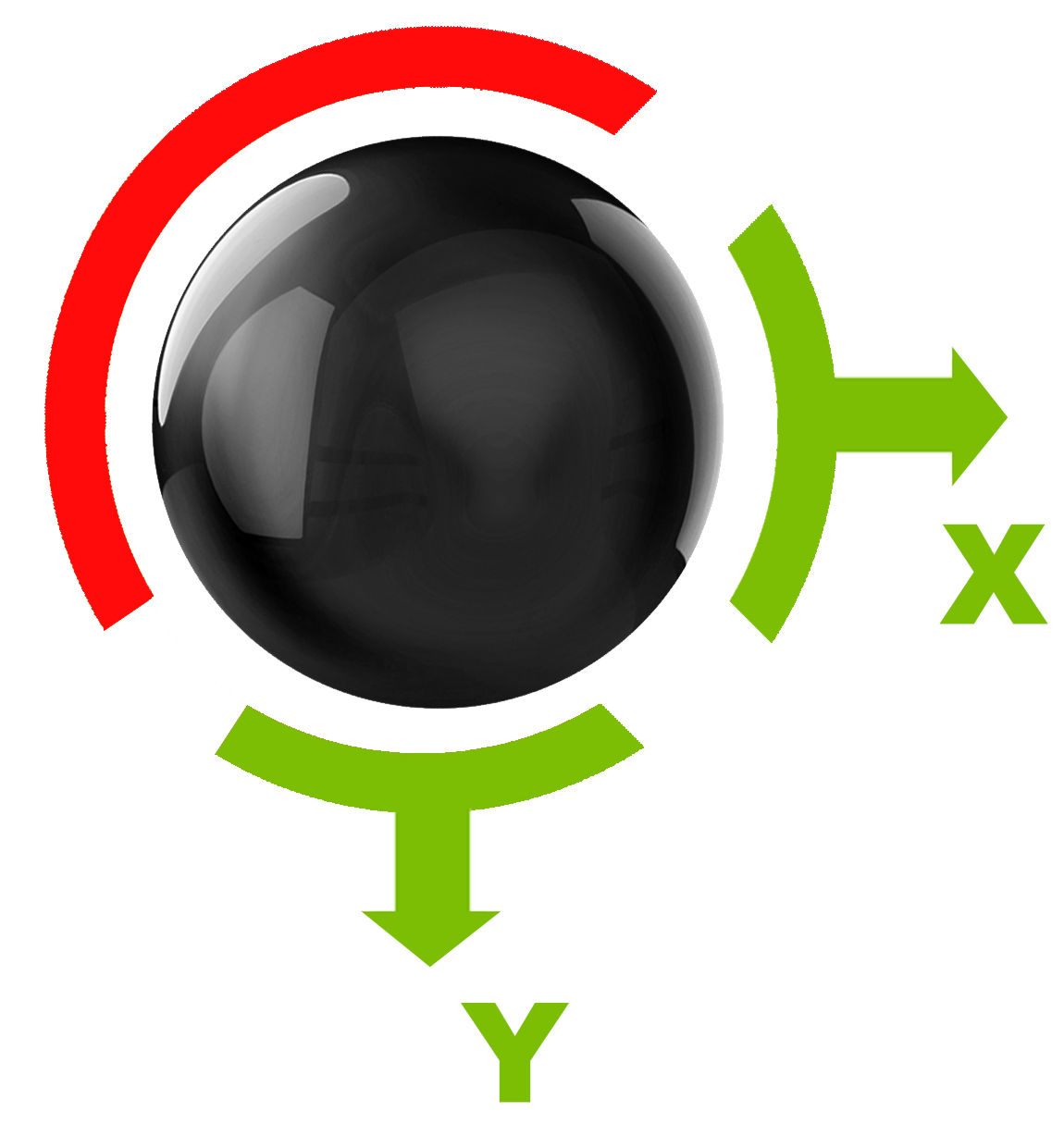

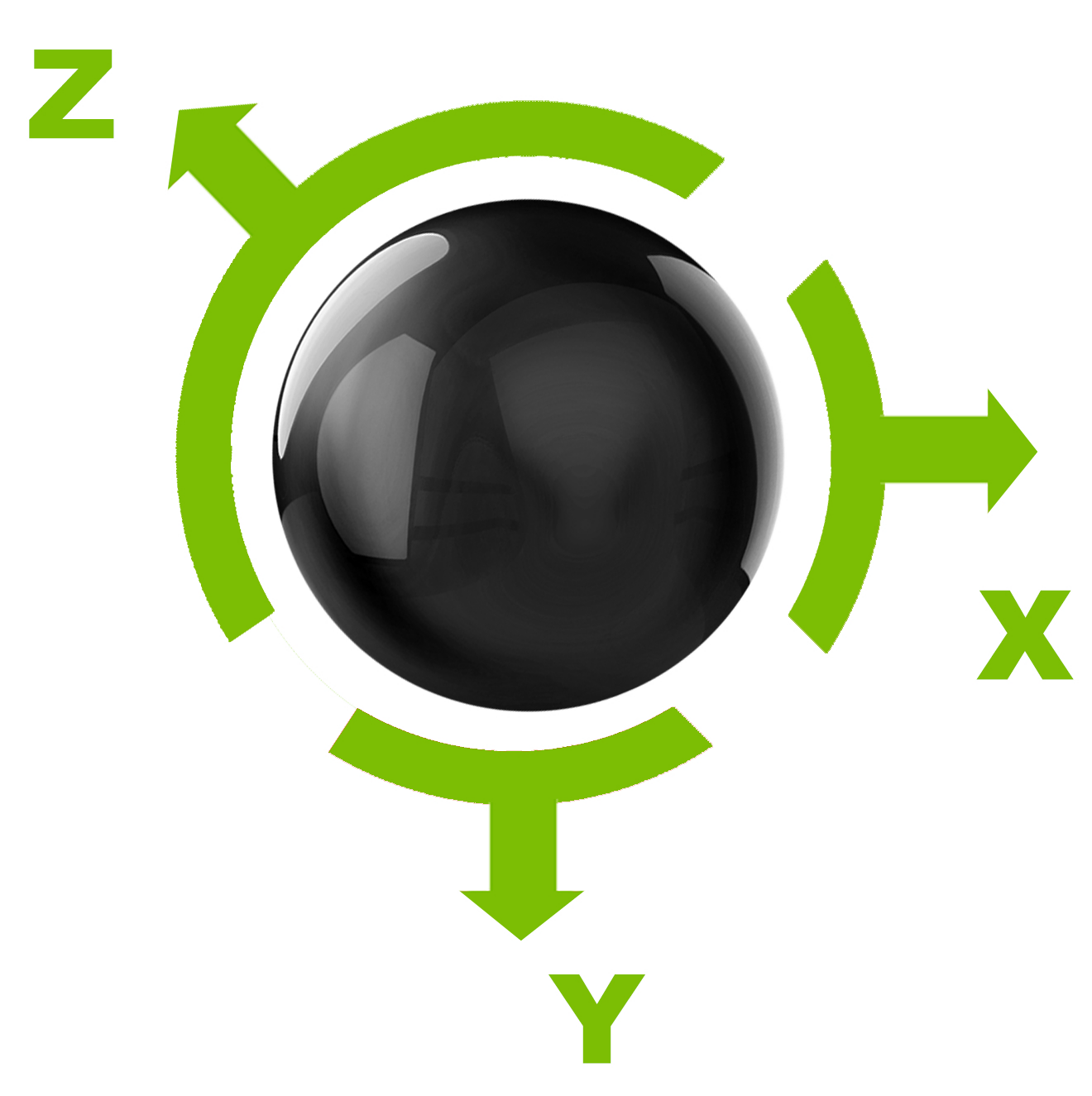

Key:x = axis right / left y = axis up / down z = axis back / front

Key:x = axis right / left y = axis up / down z = axis back / frontThe Following pictograms can help you understand the direction in which the effort can be applied on our anchor points:

|  |  |  |