Thursday 24th April 2025

Slewing jib cranes are a popular choice across many industries when a permanent lifting solution is needed for both vertical lifting and limited horizontal movement. They’re commonly used over workbenches, in maintenance workshops, at machine stations, and in loading or unloading zones.These cranes provide excellent floor coverage within the slewing radius of the jib arm, making them a practical and cost-effective alternative to full overhead crane systems—especially where space or budget constraints make large systems impractical. In some cases, they’re also used to complement existing overhead cranes by covering specific work areas.

It's important to note that a slewing jib crane is only operational once it's equipped with a lifting appliance—such as a hoist, or a hoist and trolley combination. While many slewing jib arms are designed and tested without a hoist included, they must be fitted with one before they can function as a complete lifting system.

10.1 Scope of Slewing Jib Cranes

10.1.1 Types and Design

- Slewing jib cranes included in this section may be:

- Wall-mounted, column-mounted, or free-standing in design.

- Constructed using standard structural sections or proprietary track systems.

- Suitable for a variety of general-purpose lifting applications across many industrial settings.

10.1.2 Use With Lifting Appliances

These cranes are always used in conjunction with a lifting appliance—typically:

- A hand chain hoist, or

- A powered hoist, often mounted on a trolley for movement along the jib arm.

- Section 3 – Hand Chain Hoists

- Section 6 – Power Operated Hoists

- Section 8 – Travelling Girder Trolleys

10.1.3 Exclusions

The following equipment types are not covered in this section:

10.2 Definitions

- Derricking (luffing) cranes

- Lifeboat cranes

- Cranes used on offshore platforms for vessel loading/unloading

- Cranes used for lifting or transporting people

10.2 Definitions

This section explains the key terms specific to slewing jib cranes, building on the general definitions already outlined in Section 1.2 of the LEEA Code.

10.2.1 – Slewing Jib Crane

A slewing jib crane consists of a cantilevered beam or horizontal jib arm, mounted on a king post that sits in bearing brackets. It can be:

- Wall-mounted or column-mounted, using an existing structure, or

- Free-standing, built into a custom support column.

10.2.2 – Slew (or Slewing)

Slewing refers to the rotary movement of the jib arm around a vertical axis. The angle of slew is the arc covered by the jib arm between its furthest rotation points.

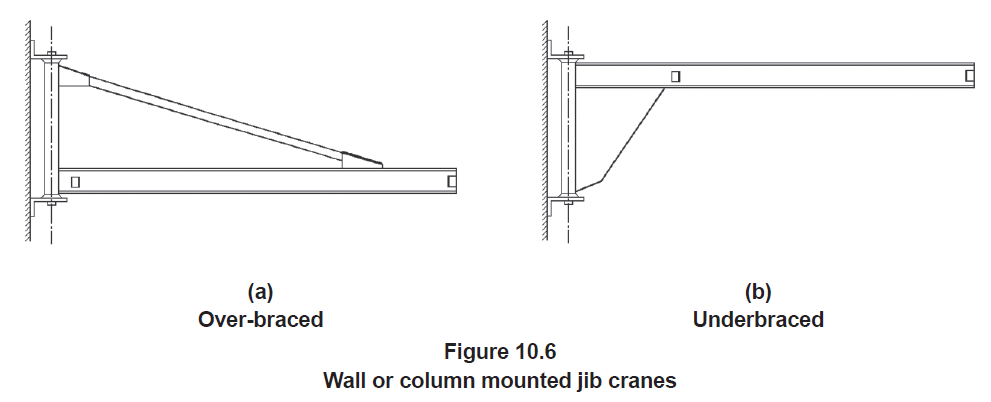

10.2.3 – Overbraced

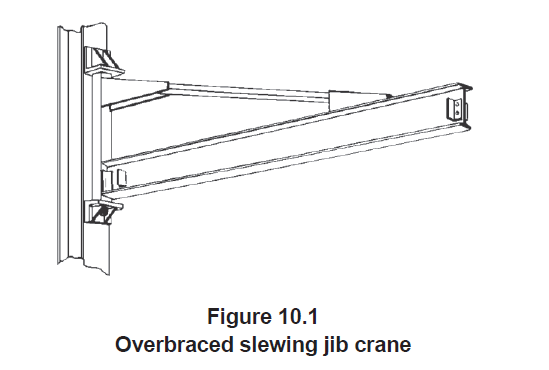

A jib is overbraced when its horizontal arm is supported from above by angled bracing.

A jib is overbraced when its horizontal arm is supported from above by angled bracing.

10.2.4 – Underbraced

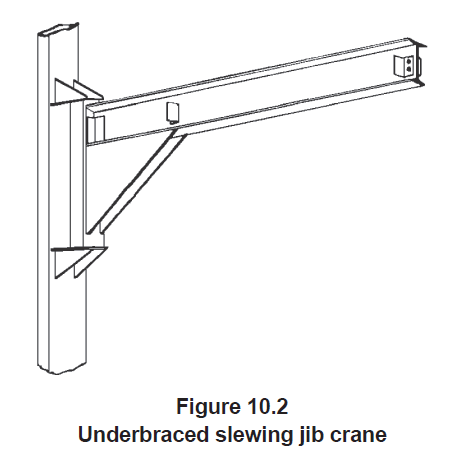

A jib is underbraced when its horizontal arm is supported from below by angled bracing.

🖼️ (See Figure 10.2: Underbraced Slewing Jib Crane)

A jib is underbraced when its horizontal arm is supported from below by angled bracing.

🖼️ (See Figure 10.2: Underbraced Slewing Jib Crane)

10.2.5 – King Post

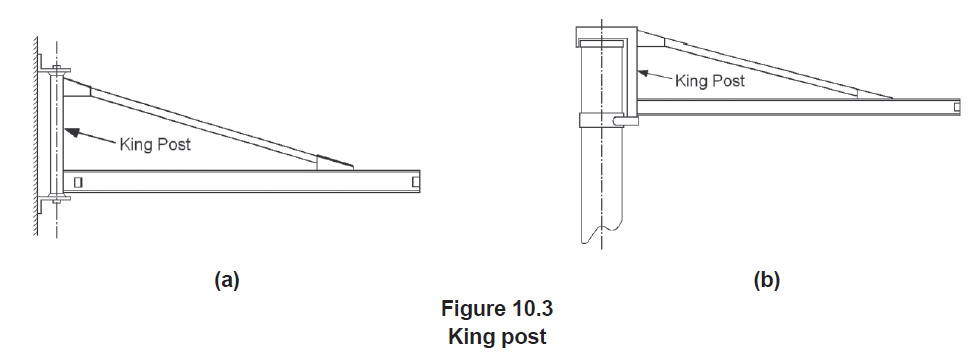

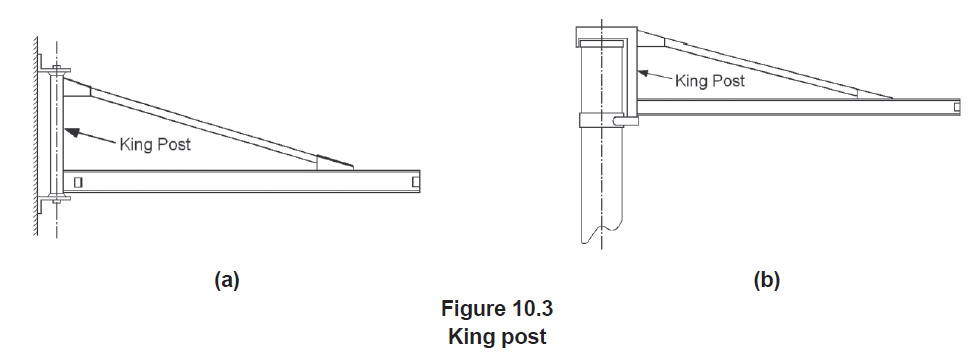

The king post is the main upright structure to which the jib arm and bracing are connected. It may be:

The king post is the main upright structure to which the jib arm and bracing are connected. It may be:

- A vertical shaft with top and bottom journals that rotate in bearings (Figure 10.3a), or

- A fabricated section with spigots and rollers designed for tubular column jibs (Figure 10.3b).

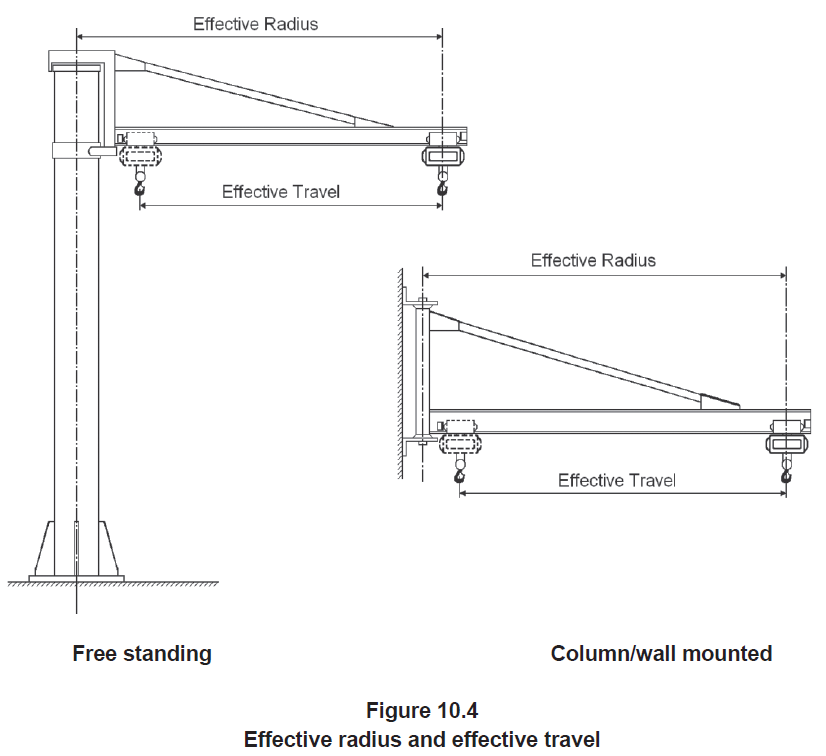

10.2.6 – Effective Radius

The effective radius is the horizontal distance from the center of rotation to the outermost point where the lifting hook aligns vertically.

🖼️ (See Figure 10.4)

The effective radius is the horizontal distance from the center of rotation to the outermost point where the lifting hook aligns vertically.

🖼️ (See Figure 10.4)

10.2.7 – Effective Travel

This refers to the distance the hoist or trolley can move along the jib arm, measured between fixed end stops.

🖼️ (See Figure 10.4)

This refers to the distance the hoist or trolley can move along the jib arm, measured between fixed end stops.

🖼️ (See Figure 10.4)

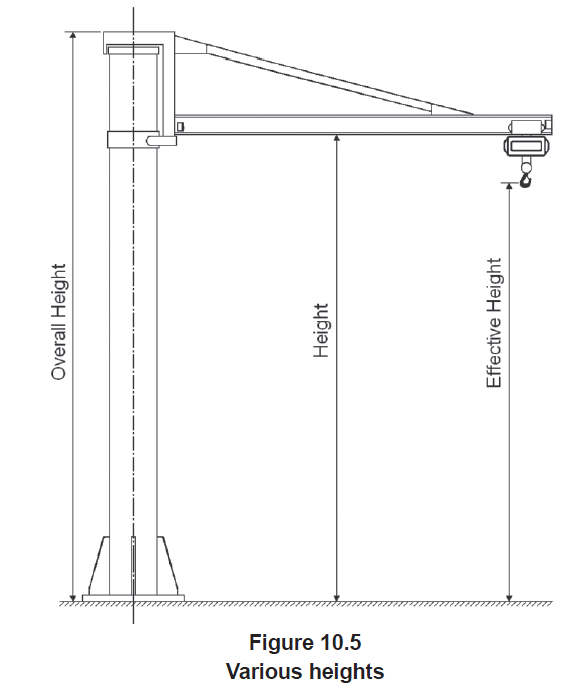

10.2.8 – Height

- Height is measured from the floor to the underside of the jib arm.

- Overall height is measured from the floor to the highest point of the crane.

10.2.9 – Effective Height

The effective height is the vertical distance from the floor to the bottom hook seat when the hoist is in its fully raised position.

🖼️ (See Figure 10.5)

The effective height is the vertical distance from the floor to the bottom hook seat when the hoist is in its fully raised position.

🖼️ (See Figure 10.5)

10.3 Types of Slewing Jib Cranes

Slewing jib cranes come in two primary types, each available in overbraced or underbraced configurations depending on the application and space constraints.

10.3.1 – Wall or Column Mounted Jib Cranes

In this setup, the jib arm, king post, and bracing are pre-assembled into a single unit. These can be either:

In this setup, the jib arm, king post, and bracing are pre-assembled into a single unit. These can be either:

- Wall-mounted, using drilled bolt holes in the brackets.

- Column-mounted, using clamp fixings that wrap around a structural column.

Slewing Angle:

- Wall-mounted jibs typically offer a 180° angle of slew.

- Column-mounted jibs can reach up to 270°, depending on the length and design of the brackets.

- Stops may be installed to limit the swing to any desired position within the arc.

10.3.2 – Free Standing Jib Cranes

These cranes include a fully integrated column, arm, and bracing—built as a standalone unit. Like wall-mounted types, they can be overbraced or underbraced depending on use and location.

🔧 Column Types:

⚙️ Slewing Features:

🔧 Column Types:

- Tubular columns allow for continuous 360° rotation.

- Box or fabricated sections typically allow up to 270° slew, with stops to limit the swing.

- Slip ring units are used for electric hoists when 360° rotation is required—avoiding cable twisting.

- For pneumatic hoists, the air is routed internally through the column and along the jib via a flexible hose. In these cases, rotation must be limited to avoid damaging hoses or fittings.

Foundation Options

1- Surface Mounted

– Base plate drilled to accept anchor bolts.

2- Cast-in Foundation

– Column extended below ground to counteract turning moments.

1- Surface Mounted

– Base plate drilled to accept anchor bolts.

2- Cast-in Foundation

– Column extended below ground to counteract turning moments.

🖼️ (See Figure 10.7 for foundation design)

10.4 Principles for Selecting Slewing Jib Cranes

Choosing the right slewing jib crane involves evaluating a number of technical, operational, and safety considerations. This section outlines key factors to ensure your selection meets both your performance needs and legal requirements

10.4.1 – Application Fit

Slewing jib cranes can be:

Slewing jib cranes can be:

- Custom-built for specific tasks

- Configured from standard kits, offering quicker and more economical solutions

10.4.2 – Selecting the Right Jib Crane

Several design and site-related considerations must guide your selection:

1- Wall or Column Mounted Cranes

Overbraced Jibs

✔️ Maximize travel and coverage

❌ Require significant overhead clearance

Underbraced Jibs

✔️ Provide maximum lifting height

❌ Reduce effective travel near the support column

4- Hybrid Option

🛑 Use slewing stops where needed to avoid collisions with machinery, walls, or nearby cranes.

Several design and site-related considerations must guide your selection:

1- Wall or Column Mounted Cranes

- A qualified engineer must verify the supporting structure’s ability to withstand the added loads.

- Require engineered foundations considering column type, soil loading, mounting method, and imposed forces.

Overbraced Jibs

✔️ Maximize travel and coverage

❌ Require significant overhead clearance

Underbraced Jibs

✔️ Provide maximum lifting height

❌ Reduce effective travel near the support column

4- Hybrid Option

- Underbraced jibs with spaced bracing allow trolley passage, but reduce slewing angle and increase arm width.

10.4.3 – Choosing a Lifting Appliance

Your lifting appliance (hoist) should match both the task and the crane design:

- Hand chain, electric, or pneumatic hoists

- Match hoist capacity to the crane's Safe Working Load (SWL) to avoid confusion

- Consider the hoist size, weight, and how it affects end approach and slewing limits

10.4.4 – Slewing Mechanism Selection

Jib arms can slew:

Jib arms can slew:

- Manually by pushing the load

- Using manual gears

- By powered rotation

- Obstructions at ground level

- Suspended load positions

- Hazardous load types

🛑 Use slewing stops where needed to avoid collisions with machinery, walls, or nearby cranes.

10.4.5 – General Considerations

Other key factors to keep in mind:

1- Power Supply Requirements

Other key factors to keep in mind:

1- Power Supply Requirements

- Ensure access to a suitable power source with isolation capability

- Most free-standing powered jibs are supplied with integrated power systems and isolators

- Essential to prevent trolleys from overtraveling or hitting bracing/structure

- Use internal stops to restrict travel for workflow efficiency or safety

- Standard cranes are primed and painted, but may need further treatment in harsh or sensitive environments (e.g., outdoor, humid, or food-grade applications)

- All equipment should include documentation for compliance with legislation

- If documentation is missing, arrange a thorough examination by a Competent Person

10.5 Key Information to Exchange with the Crane Supplier

When selecting or designing a slewing jib crane, clear communication between the user and the supplier or designer is essential. Since these cranes are often tailored using standard components, sharing detailed site and usage information ensures the correct specification and safe performance.

📌 A site visit by the supplier is strongly recommended to reduce miscommunication and ensure the right crane is selected for your location and application.

Essential Information to Provide:

1- Type and Style

– Wall/column mounted or free-standing

– Overbraced or underbraced

2- Safe Working Load (SWL)

– Weight and type of load to be lifted

1- Type and Style

– Wall/column mounted or free-standing

– Overbraced or underbraced

2- Safe Working Load (SWL)

– Weight and type of load to be lifted

3- Lifting Appliance

– Type to be used (e.g. electric, pneumatic, manual hoist)

4- Effective Radius

– Include both minimum and maximum, to define travel range

5- Effective Height

– Distance from floor to underside of jib arm

6- Available Headroom

– Total installation height available

7- Required Slewing Angle

– Arc of rotation needed (e.g. 180°, 270°, 360°)

8- Crane Classification

– If known, specify; otherwise, see note 2 below

9- Electric Power Feed

– Type required, with voltage, phase(s), and frequency

10- Pneumatic Power Feed

– Type required, with pressure and airflow rate

– Type to be used (e.g. electric, pneumatic, manual hoist)

4- Effective Radius

– Include both minimum and maximum, to define travel range

5- Effective Height

– Distance from floor to underside of jib arm

6- Available Headroom

– Total installation height available

7- Required Slewing Angle

– Arc of rotation needed (e.g. 180°, 270°, 360°)

8- Crane Classification

– If known, specify; otherwise, see note 2 below

9- Electric Power Feed

– Type required, with voltage, phase(s), and frequency

10- Pneumatic Power Feed

– Type required, with pressure and airflow rate

For Free-Standing Jib Cranes:

- Size and type of column

- Fixing details (bolt type, grade, size, PCD)

- Minimum foundation dimensions

- Downward load reaction

- Turning moment at full outreach

For Wall/Column-Mounted Jib Cranes:

- Type of mounting bracket

- Max reaction force on top and bottom brackets

Environmental and Safety Conditions:

- Indoor or outdoor use

- Exposure to corrosive or hazardous environments

- Handling of dangerous or sensitive loads

Surface Finish and Paint:

- Special coatings, finishes, or colours (e.g. for food handling, outdoor exposure, or safety marking)

Other Special Requirements:

- Flameproofing or hazardous zone compliance

- Unique technical specifications

- Installation and maintenance instructions

Notes:

(1) Structural and foundation-related data from items 11 and 12 should be confirmed by a qualified engineer as per Section 10.4.2.

(2) If crane classification is unknown, provide:

Estimated utilization:

(1) Structural and foundation-related data from items 11 and 12 should be confirmed by a qualified engineer as per Section 10.4.2.

(2) If crane classification is unknown, provide:

Estimated utilization:

- Lifts per hour

- Daily/Monthly usage

- Lifts at 100%, 75%, 50%, and 25% of SWL

- Weight of lifting appliance (if known)

- Desired design life (in years)

📣 Final Tip

If you’re unsure about any details, consult your supplier. Their guidance ensures you get the most suitable and compliant jib crane for your needs. Always follow any restrictions or recommendations provided.

10.6 Legal Requirements

When it comes to slewing jib cranes, compliance with health and safety legislation is critical. This section outlines the key legal responsibilities for suppliers, purchasers, and users.

📌 For broader legislative context, refer also to Section 1.3 of the LEEA Code of Practice.

10.6.1 – Documentation on Supply

1- If the crane is supplied without electrics or a hoist, the supplier must provide written documentation confirming:

1- If the crane is supplied without electrics or a hoist, the supplier must provide written documentation confirming:

- Compliance with essential health and safety requirements

- Any standards used in the structure's design and manufacture

- Information for use to ensure safe operation

- Be clearly marked

- Be delivered with all relevant legal documentation

- Comply with the applicable design and manufacturing standards for lifting equipment

10.6.2 – Inspection and Examination Requirements

1- Slewing jib cranes and their structural components (anchors, fixings, supports) are classified as lifting equipment.

2- Unless a written scheme of examination (per LEEA 032) is in place, cranes must undergo:

1- Slewing jib cranes and their structural components (anchors, fixings, supports) are classified as lifting equipment.

2- Unless a written scheme of examination (per LEEA 032) is in place, cranes must undergo:

- Thorough examination by a Competent Person at intervals not exceeding 12 months

- Retained

- Cross-referenced with the crane's historical records

- Available for inspection by enforcement authorities or Competent Persons

10.6.3 – Post-Installation Inspection

1- After initial installation or relocation, cranes must be:

1- After initial installation or relocation, cranes must be:

- Thoroughly examined by a Competent Person before first use

- Typically include a proof load test

10.6.4 – Post-Repair Verification

- After any repair work, especially to the foundation or fixings, the crane must be:

- Re-verified by a Competent Person

10.7 Installation and Commissioning

Proper installation and commissioning of a slewing jib crane are essential for ensuring safety, performance, and legal compliance. This section outlines best practices for assembly, inspection, and testing.

🛠️ 10.7.1 – Equipment Installation

Follow the manufacturer’s instructions during erection, while paying close attention to these critical factors:

1- Structural Safety & Foundation

Follow the manufacturer’s instructions during erection, while paying close attention to these critical factors:

1- Structural Safety & Foundation

- The crane's safety relies on secure foundations or structural supports.

- If wall- or column-mounted, a qualified engineer must verify that the existing structure can support the loads.

- Free-standing cranes must be mounted on foundations capable of resisting the overturning moment. (Refer to 10.4.2)

- For clamp-mounted jibs (e.g. on structural columns), prevent slippage by fitting positive stops beneath the clamps.

- Adjust the trolley to match the beam width.

- If installed from the end of the jib, ensure all bolts and end stops are re-secured properly. (See Section 8)

- Install the hoist and, if applicable, the electrical or pneumatic feed as per the manufacturer’s guidelines.

- Refer to:

- Section 6 for power-operated hoists

5- Final Structural Checks

- Confirm all bolts and fixings are in place and tightened.

- Ensure:

- End stops and slewing stops are fitted and correctly positioned

- Any pre-use system checks for the hoist or power feed are complete

🧪 10.7.2 – Pre-Use Inspection & Thorough Examination

Before the crane enters service, a Competent Person must conduct a thorough examination that typically includes:

- Lifting appliance

- Power feed system

🧾 Testing Standards

Before the crane enters service, a Competent Person must conduct a thorough examination that typically includes:

- Structural verification and installation checks

- Load testing, even if electrical/mechanical systems were pre-tested at the factory

- Proof load test at 1.25x the Safe Working Load (SWL)

- Inspection of:

- Lifting appliance

- Power feed system

🧾 Testing Standards

- Tests should follow the design standard for the crane.

- The manufacturer provides the maximum permissible deflection, which is compared against test results.

- A variation of more than ±10% in deflection indicates a potential installation issue.

- Trolley does not roll uncontrollably when loaded

- Gradient of jib arm allows smooth trolley travel

- Arm does not slew on its own

- Load can be accurately positioned

📄 Certification & Reporting

- Be retained with the engineer’s written approval

- Be cross-referenced to the crane’s service history (See Section 10.6)

- On successful completion of tests, the Competent Person must issue a report of thorough examination.

- If the hoist is detachable from the jib, it may require a separate proof test.

- Reports should:

- Be retained with the engineer’s written approval

- Be cross-referenced to the crane’s service history (See Section 10.6)

10.8 Marking and Storage (Section 10.8)

Correct identification and safe storage of slewing jib cranes are essential for compliance, traceability, and workplace safety. This section outlines key marking requirements and storage guidelines.

10.8.1 – Marking Requirements

Each slewing jib crane must be permanently and clearly marked in accordance with the applicable legislation and standards. The following information should be legibly displayed on a suitable part of the crane:

1- Identification Mark or Serial Number

- Display the words "Manual Hoist"

Each slewing jib crane must be permanently and clearly marked in accordance with the applicable legislation and standards. The following information should be legibly displayed on a suitable part of the crane:

1- Identification Mark or Serial Number

- If no serial number is supplied by the manufacturer, the user must apply a unique identifier to link with inspection and examination reports.

- Clearly marked on both sides of the jib arm

- Must be visible from operating level

- Where applicable, indicate the design/manufacturing standard

- If supplied without a lifting appliance:

- Display the words "Manual Hoist"

5- Manufacturer or Supplier Name

🔒 Important Reminder:

Always ensure the total load, including the lifting equipment’s weight, does not exceed the SWL. This is especially critical if the hoist is regularly changed out, such as in maintenance applications.

- Ensure traceability

- As defined by crane duty classification

🔒 Important Reminder:

Always ensure the total load, including the lifting equipment’s weight, does not exceed the SWL. This is especially critical if the hoist is regularly changed out, such as in maintenance applications.

📦 10.8.2 – Storage Guidelines

To maintain safety and prevent hazards during downtime:

- Consider securing the jib arm to prevent unwanted movement caused by wind or vibrations

To maintain safety and prevent hazards during downtime:

- When not in use, position the jib arm so it does not obstruct people, goods, or vehicles in the area

- If the crane is used infrequently:

- If removal is not practical, then:

- Consider securing the jib arm to prevent unwanted movement caused by wind or vibrations

10.9 In-Service Inspection and Maintenance

Regular inspection and maintenance of slewing jib cranes are essential for ensuring ongoing safety, preventing faults, and complying with legal and manufacturer standards. This section outlines different types of inspections and ongoing maintenance recommendations.

👁️ 10.9.1 – Pre-Use Inspection

Before each use—or daily for frequently used cranes—a qualified and experienced person should carry out a visual inspection.

Before each use—or daily for frequently used cranes—a qualified and experienced person should carry out a visual inspection.

🔍 Best Practices:

🧯 Key Things to Check:- Inspect at the start of each shift for regular-use cranes

- For occasional-use cranes, inspect before each use

- Maintain a written record including:

- Inspection date

- Inspector's name and signature

- Confirmation that the equipment passed

- If faults are found, the crane must be quarantined until resolved

- Corrosion, deformation, or damage to the structure (e.g. bent jib arm, twisted column)

- Cracked or crumbling walls (for wall-mounted cranes)

- End stops – ensure they’re effective, correctly bolted, and not making contact with trolley wheel flanges

- Loose/missing bolts or washers, including foundation fixings

- Foundation bolt movement – follow manufacturer guidance or consult a Competent Person

- Slewing issues – difficulty rotating or uncontrolled movement

- Load behaviour – runaway trolleys, difficulty moving loads may indicate overloading or damage

🧾 10.9.2 – Interim Inspection

These are risk-based inspections carried out between pre-use checks and annual thorough examinations.

🔧 Purpose:

These are risk-based inspections carried out between pre-use checks and annual thorough examinations.

🔧 Purpose:

- Detect deterioration based on operating conditions

- Focus on critical components, not full structural review

- Often done alongside planned maintenance

🧰 10.9.3 – Routine Maintenance

Establish a preventive maintenance programme in line with the manufacturer’s instructions and site-specific conditions.

✅ Areas to Maintain:

Establish a preventive maintenance programme in line with the manufacturer’s instructions and site-specific conditions.

✅ Areas to Maintain:

- Lubrication – Bearings, gears, and slewing mechanisms must be regularly lubricated

- Track cleaning – Keep trolley path free of debris; clean wheels

- Structural integrity – Check bolts, fixings, and supports; re-torque or replace as needed

- End and slewing stops – Inspect and verify positioning

- Electrical systems –

- Inspect entry glands and flexible cables for wear

- Check slip rings, carbon buildup, brushes, and collectors

- Conduct regular insulation and earth continuity tests

6. Pneumatic systems –

- Inspect flexible hoses, filters, lubricators

- Check connectors for looseness or wear

- Top up oil and drain moisture as required

🔍 10.9.4 – Thorough Examination

A Competent Person must thoroughly examine each crane at least once every 12 months, unless an approved written scheme of examination is in place (see LEEA 032 guidance).

📝 Requirements:

The Competent Person may carry out:

Routine overload testing is not recommended unless following:

10.10 Safe Use of Slewing Jib Cranes

A Competent Person must thoroughly examine each crane at least once every 12 months, unless an approved written scheme of examination is in place (see LEEA 032 guidance).

📝 Requirements:

- Use LEEA templates or legally compliant report formats

- Store reports with the crane's historical records

- Notify owners of any defects and their root causes

- Implement corrective actions (e.g. training, increased inspections) before returning to service

The Competent Person may carry out:

- NDT (Non-Destructive Testing)

- Functional tests

- Overload tests, if deemed necessary

Routine overload testing is not recommended unless following:

- Major repairs

- Significant modifications

- Exceptional events

- Accelerated wear or fatigue damage

- Possibility of equipment failure

- No structural benefit under normal conditions

10.10 Safe Use of Slewing Jib Cranes

To ensure safety during lifting operations, users must follow the manufacturer’s safety instructions and adhere to the general safe-use practices outlined below.

✅ Key Safety Guidelines

1- Respect the SWL (Safe Working Load)

- Increased mechanical stress due to extended radius and dynamic forces

1- Respect the SWL (Safe Working Load)

- Never exceed the crane’s marked SWL.

- Always factor in the weight of the hoist, slings, and lifting accessories—these reduce the crane’s effective lifting capacity.

- Do not drag loads using the hook or crane travel motion.

- Misalignment causes the jib arm to swing and may cause trolley whipping during lift.

- Take up the load gently.

- Confirm all attachments are secure.

- Avoid shock loads—especially important during trial lifts or when setting loads down.

- Ensure the path of the jib arm and load is clear before movement.

- Operators must maintain full visibility of the travel path.

- For hand-push cranes or trolleys, push the load—this gives better control and safety.

- Load swing increases the risk of:

- Increased mechanical stress due to extended radius and dynamic forces

8- Avoid Shock Loading

- Sudden lifts, stops, or movements can impose dangerous forces on the crane structure.

- When lifting or positioning items like machine tool parts or chucks, avoid swing or jarring motion.

- Switching to a powered hoist?

- Ensure the weight and motion of the new hoist is within the crane’s original design limits

- If unsure, consult a Competent Person

10.11 Training Requirements

Proper training is essential to ensure the safe and effective use of slewing jib cranes. In addition to the guidance provided in Section 1.9 of this code, the following key points should be addressed when training operators.

🎓 Essential Training Considerations

1- Visual and Spatial Awareness

1- Visual and Spatial Awareness

Operators must:

- Have good eyesight

- Be able to accurately judge distances, heights, and clearances

- Receive specific training that develops these spatial awareness skills in the context of crane operation

- Where manual pushing or pulling of the load is required (e.g., for hand-push trolleys or cranes), the operator should be:

- Trained on how to safely manoeuvre loads without overexertion or strain

📘 Note: Always incorporate the manufacturer’s instructions into the training programme to ensure equipment-specific best practices are included.