Thursday 15th December 2022

Under The Hook

To connect crane hook and load safely, the so-called "under-the-hook devices" are needed. Here you learn about the device group slings. Slings are used to connect crane and load and enable safe transport. Due to a variety of lifting applications various sling options are possible, chain slings, wire rope slings and textile slings.

Crane Hook Often the crane hook cannot lift loads directly so between the crane hook and the Load, further components are needed.

Slings: Slings (“hangers”) are used to create a connection between the crane hook and the load in most case, chain slings , wire rope slings or textile slings are used.

Lifting Points: A common method of establishing a connection is us to use lifting points that can be attached to the Load

In every industry, it is necessary to safely lift and move loads. Most lifting applications are realized by one of these sling types: chain, wire rope and textile. Learn about the most important features of the three sling types:

Chain Slings

Chain slings use tested, short-link chains, standardized (EN 818) in different grades for lifting purposes. The standards prescribe high requirements on performance and quality and make sling chains a high-quality and top performance product, that can be used worldwide. As safety is the top priority of sling chains, every individual link is tested beyond the working load limit and every individual lot is checked on the quality of the production. This guarantees best quality and highest safety of sling chains for use.

Pewag offers sling chains and equipment in grade 10 (winner) and 12 (winner pro). To meet special customer requirements, Our supplier Pewag also offers reliable products for stainless steel applications (winner inox) and hot-dip galvanizing plants (winner fire).

Pewag offers sling chains and equipment in grade 10 (winner) and 12 (winner pro). To meet special customer requirements, Our supplier Pewag also offers reliable products for stainless steel applications (winner inox) and hot-dip galvanizing plants (winner fire).

Textile Slings

Textile slings consist of textile fabrics and are standardized for general lifting purposes according to EN 1492. Only high-strength multifilament made of technical yarns (polyamide (PA), polyester (PES), polypropylene (PP)) is permitted to be used for textile slings. For lifting purposes, textile webbing slings and round slings are used. pewag offers webbing slings and round slings as well as additionally needed equipment required for textile slings.

Wire Rope Slings

In EN 13414 wire rope slings approved for lifting are specified. Wire ropes consist of individual steel wires which together form a strand. In a pattern (“lay”) the strand is wound around an inner filler material (“core”). In order to be connectable to other components, wire ropes need an end connection. By the type of end connection and the material of the core (fiber or steel), the wire ropes differ from each other.

Assembly of chain slings

How are chain slings assembled?

Slings are assembled with different accessories, depending on the application and usage. All used accessory parts comply with EN 1677. A chain sling is a modular system, consisting of: master links, end fittings, connecting links and shortening devices. For a clear identification, an ID-tag containing its key information needs to be added. On top, the master link is attached to the crane hook. The end fittings of the sling secure that the load is safely connected. As an optional feature, the shortening device is often used, allowing the adjustment of the chain length. Depending on the way of assembly, connecting links are needed.

Different parts or components in a Chain Sling Assembly:

Master Link:

The main link is attached into the crane hook. It is designed to fit with crane hooks according to DIN 15401 and DIN 15402. In case of special requirements, customised solutions can be offered.

Connecting Link:

The connecting link is used to connect

the accessory components to a sling. For chain slings, there are three types of

connections : a welded system, a connex system using a detachableconnectinglinkandaclevissystem,

that is integrated into the accessory parts.

Shortening Device:

By shortening the length of the chain can be

adapted to the respective application. When shortening is applied , the chain

is inserted into a shortening device. A simple and safe option is to use a

shortening hook.

Chain:

For lifting purposes short linked chains

are used in different grades, such as G80, G10, or G12. The grade indicates

which mechanical load that the chain withstand.

ID TAG

The ID Tag provides all relevant information

necessary for a user to correctly perform a lifting operation. This includes

the manufacturer, the traceability code, the CE mark, the dimension, the number

of legs and thepermissibleworkingload

limit at the respective angles of Inclination.

End Hook

The end hook of a sling is attached to the load. Often this can be done directly, e.g. if lifting eyes are available on the load. If this is not the case, pewag offers lifting points with which the end hook can be securely attached to the load.

How to choose the right chain sling?

How to choose the right chain sling?

1. Number of Legs

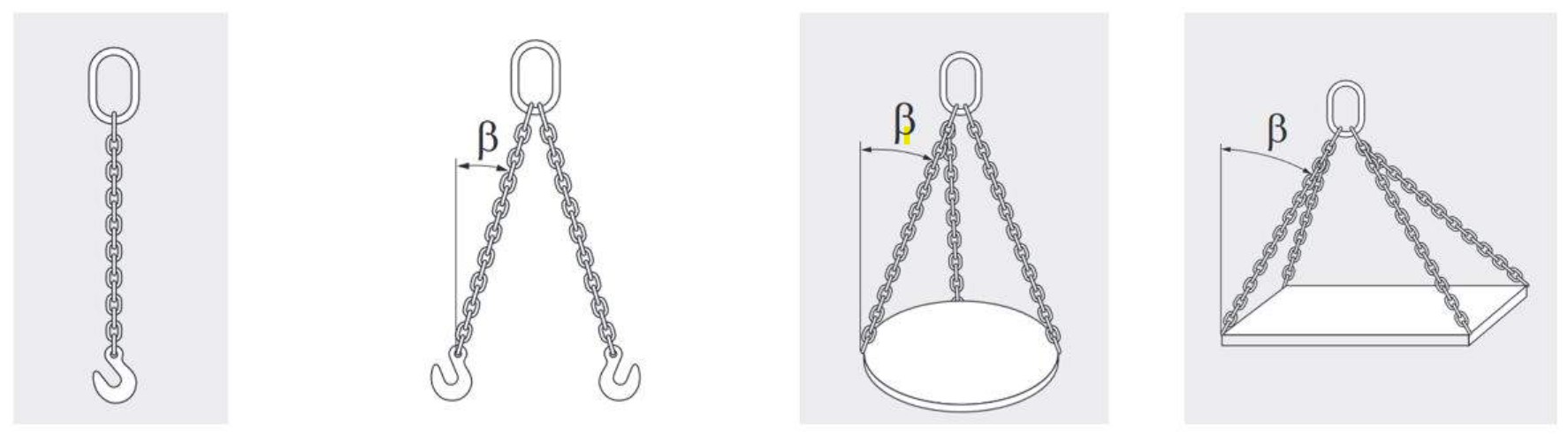

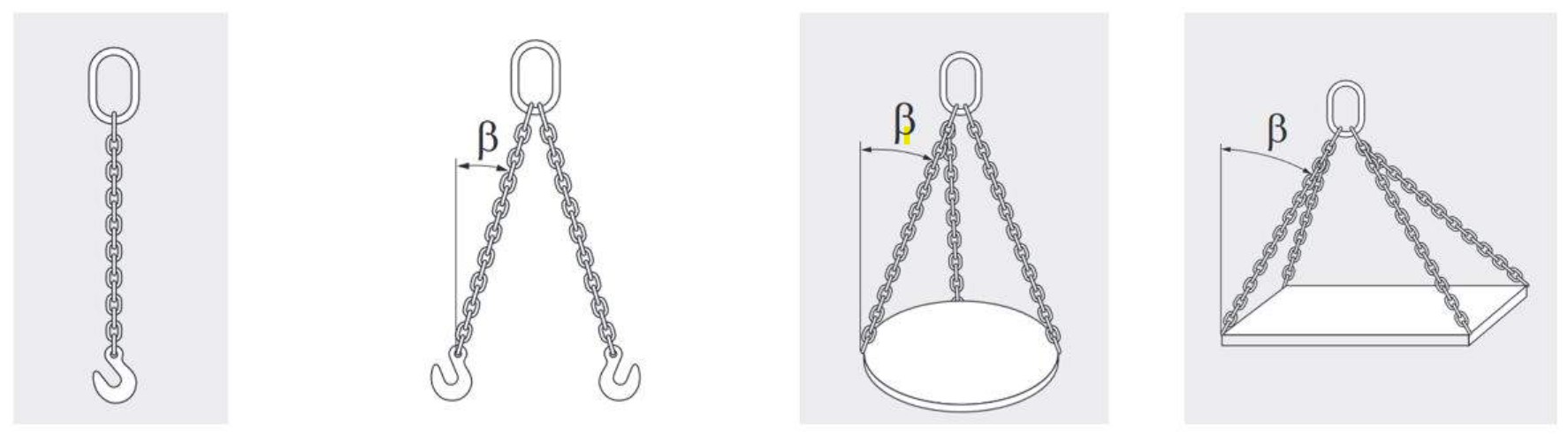

The goal is to safely attach the load to the crane hook. Depending on the application, you can choose between one-, two-, three- and four-legs. In addition, special design of chain slings is also possible, such as endless sling.

2. WLL (Working Load Limit or Capacity

The working load limit is defined by the weight of the load to be lifted.

3. Inclination Angle

For multileg chain slings, it is important to know the inclination angle (β), as it influences the chain size.

4. Dimensions of Top Fitting and End Fitting

Please consider the dimensions of the crane hook as well as the attachment point of the load. The top fitting (e.g. master link) and end fitting must match these dimensions.

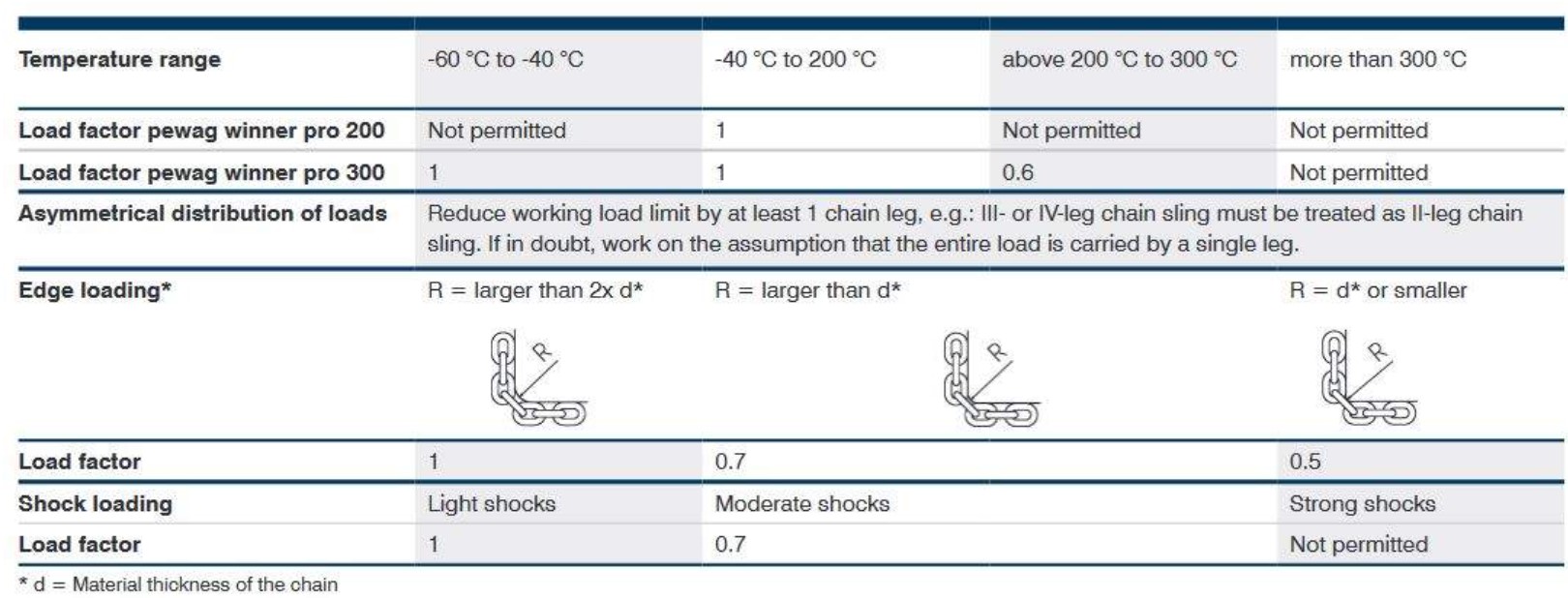

5. Possible Reduction Factors

Harsh conditions reduce the working load limit of a chain sling and are commonly referred to as reduction factors. The extent to which these factors affect the different types of slings depends on the grade. See the table below for the reduction factors of winner pro chain slings:

6. Shortening Device

A major advantage of chain slings is the flexibility to adapt the chain leg to the individually required length. The possibility to adapt the length is a unique feature of chain slings.